3

Electrical Power System Overview

3.3 USOS EPS Functional

Design

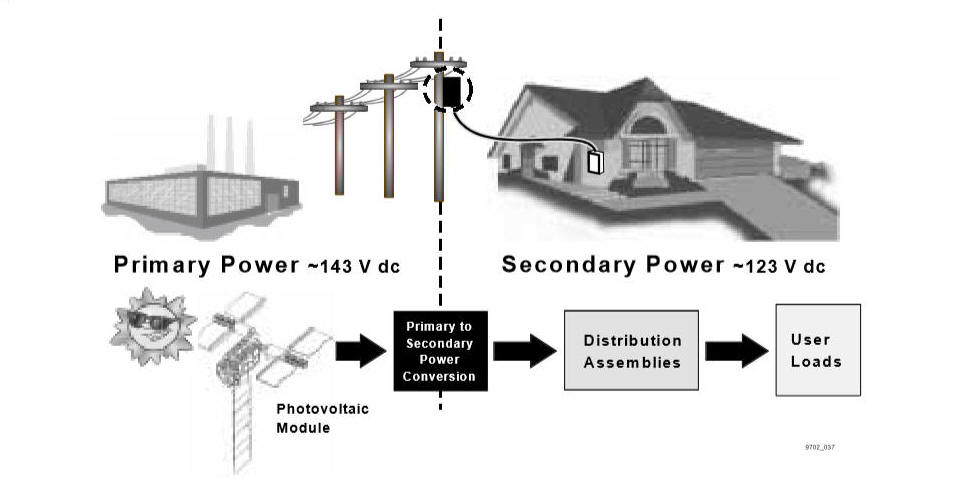

Figure 3-1.

Analogy between municipal electric utilities and ISS EPS

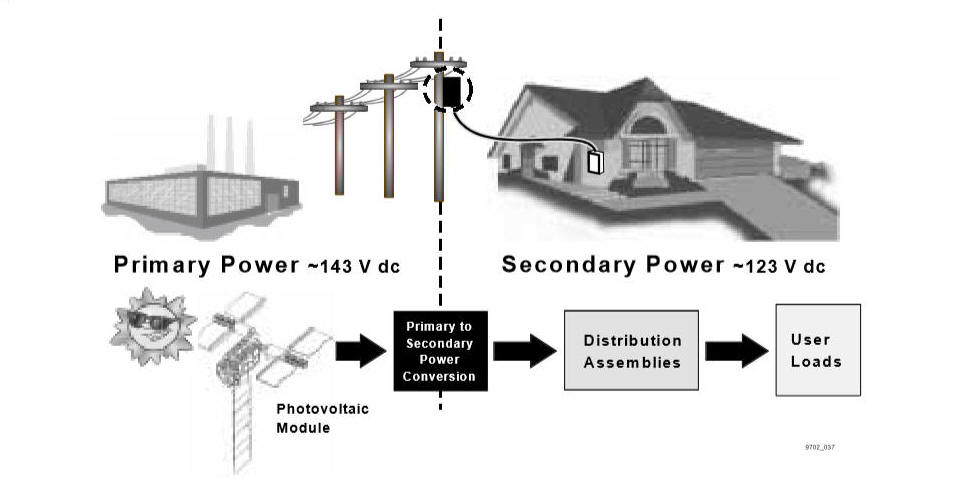

Figure 3-2. ISS at

assembly complete

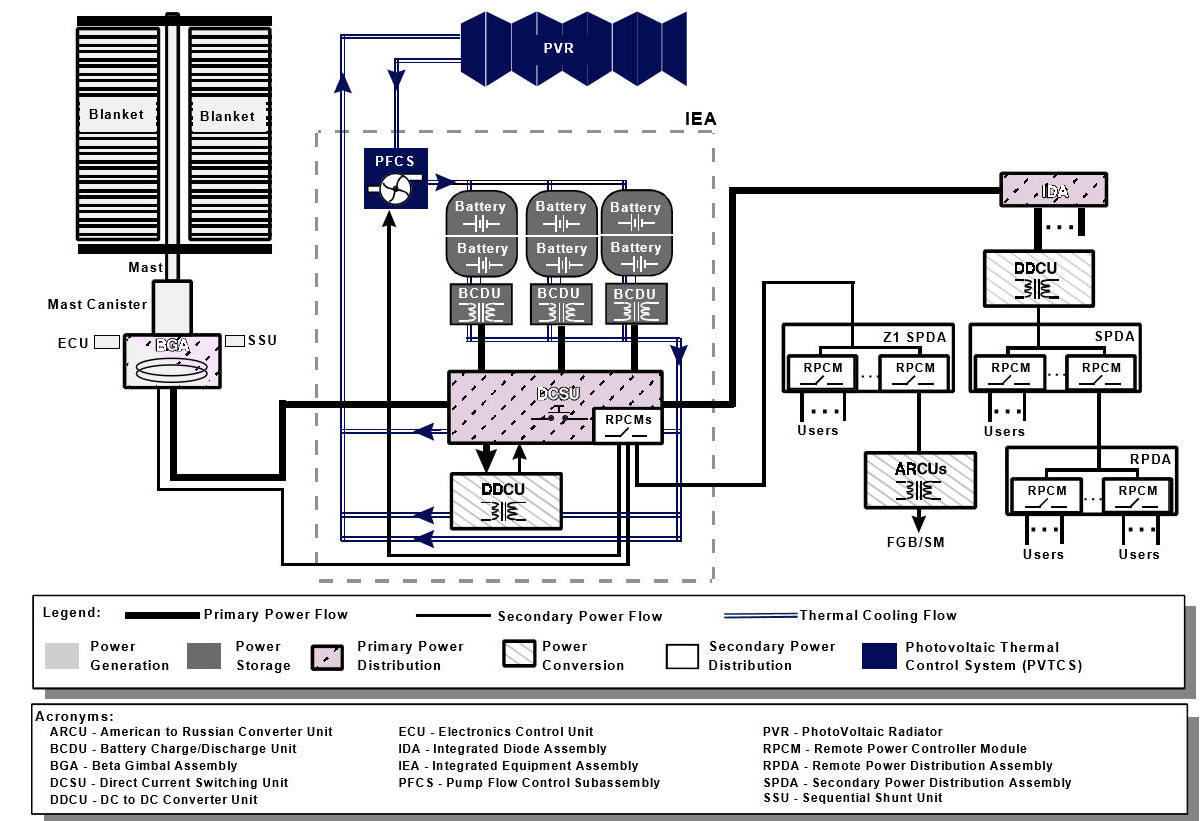

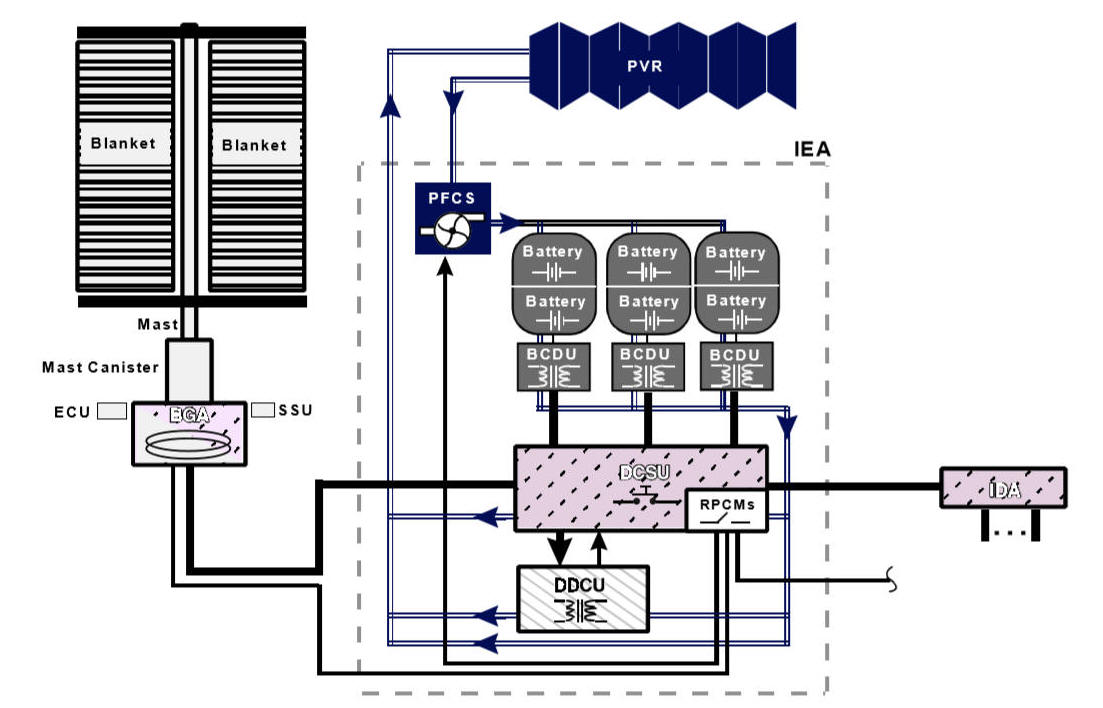

Figure 3-4. USOS EPS

schematic

Figure 3-5. USOS EPS

power channel

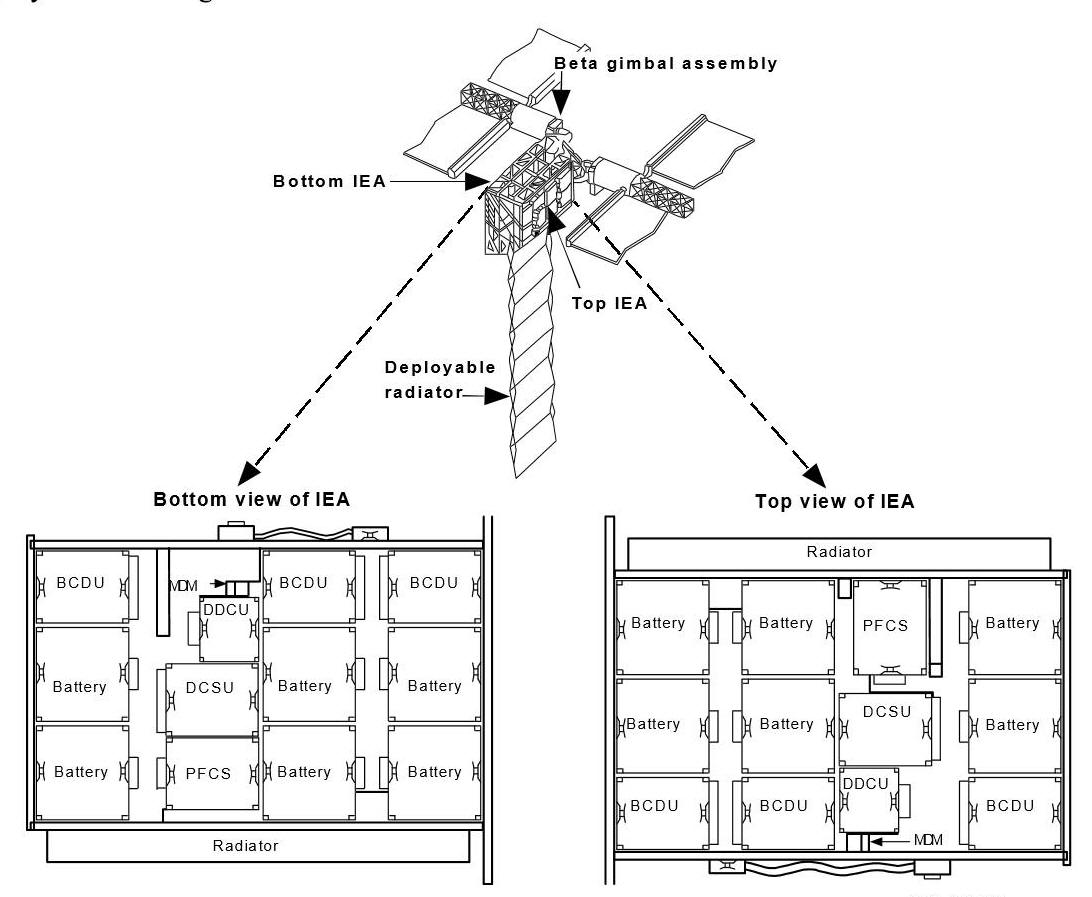

Figure 3-6.

Integrated equipment assembly

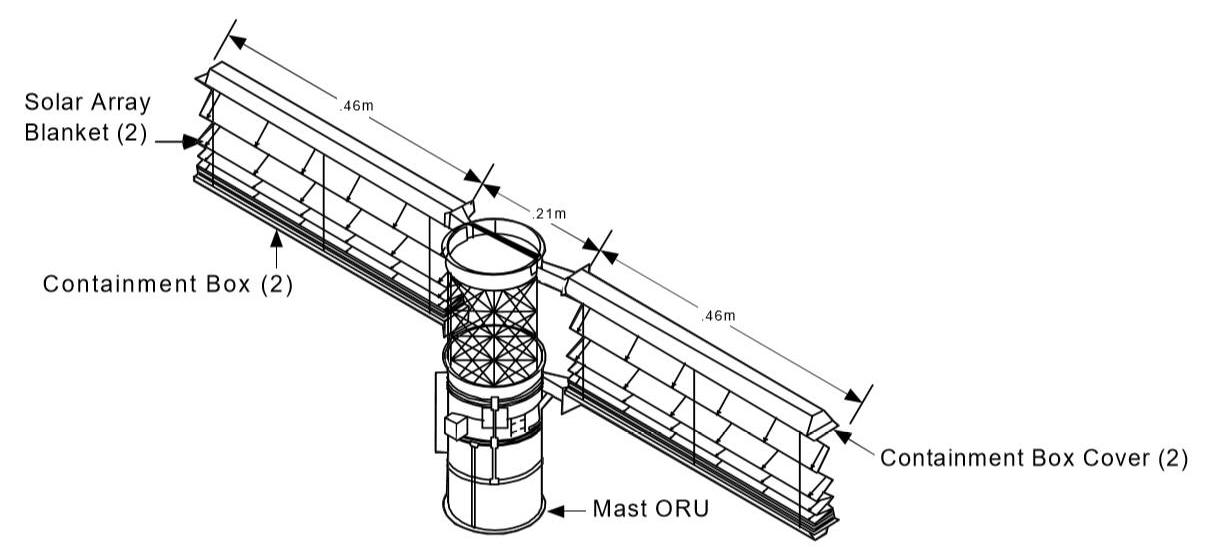

3.4.1.1 Primary Power Generation

Figure 3-7.

Partially deployed solar array wing

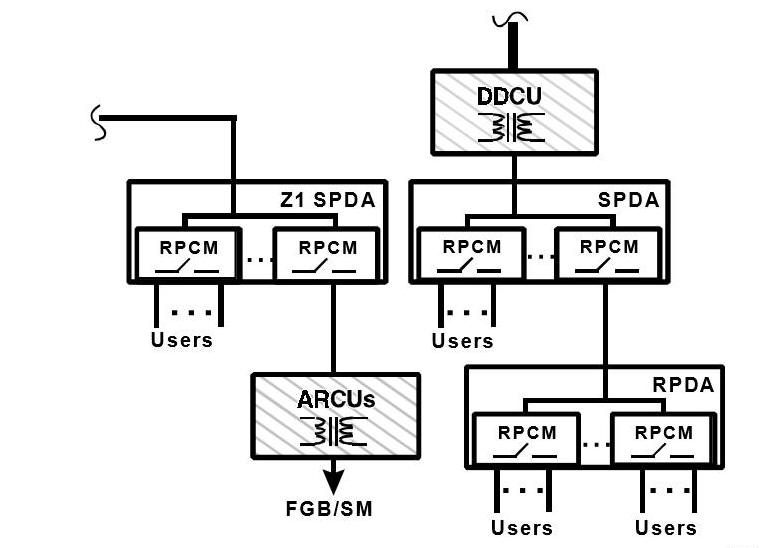

3.4.1.3 Primary Power Distribution

Figure 3-8.

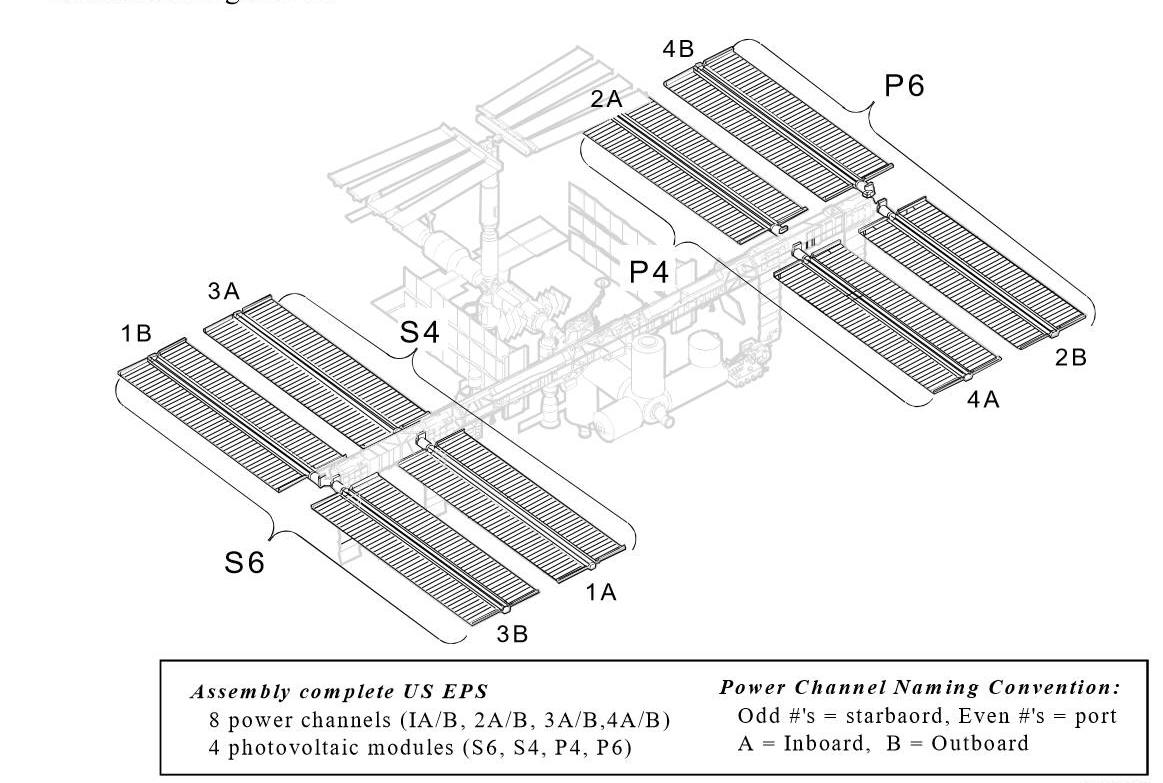

USOS secondary power system

3.4.2.1 Secondary Power Conversion

3.4.2.2 Secondary Power Distribution

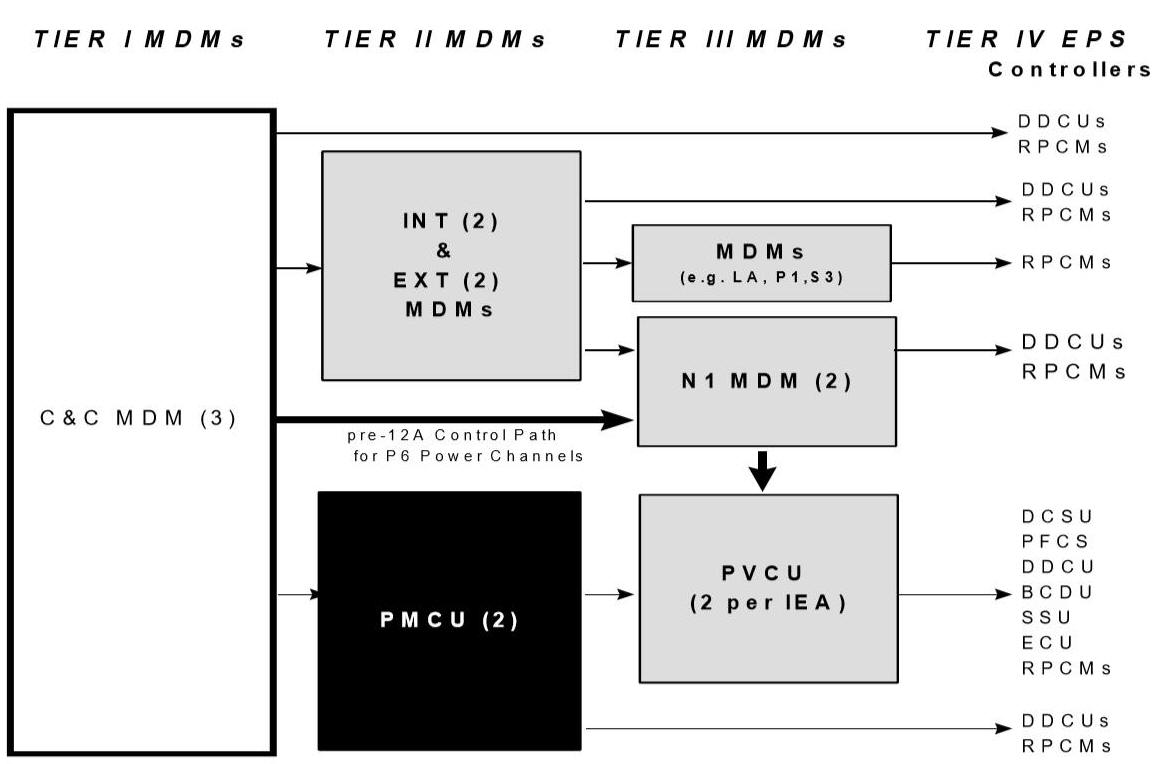

Figure

3-9. Structure of EPS command and control tiered architecture

3.4.4 USOS EPS Redundancy and

System Protection

3.5.1.1 Russian -

American Power Interface

3.5.1.2 Shuttle Power Conversion

3.5.2.1 Guidance, Navigation and Control

3.5.2.2 Command and Data Handling

3.5.2.3 Thermal Control System

3.6 Comparison between USOS and ROS

EPS

Figure 3-10.

FGB electrical system drawing

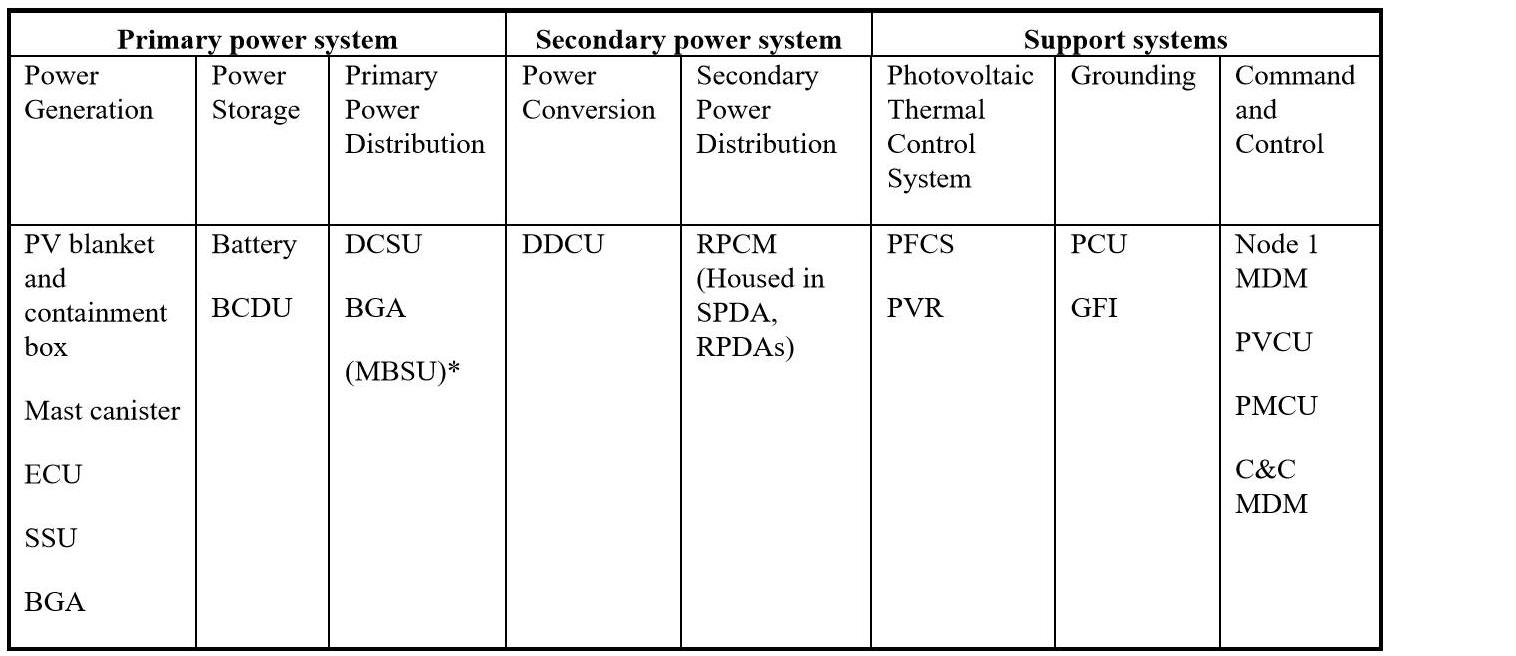

Table 3-1. USOS EPS components at flight 8A

The International Space Station (ISS) requires electrical

power for all ISS functions:

command and control, communications, lighting, life support, etc. Both the

Russian Orbital Segment (ROS) and U.S. On-orbit Segment (USOS) have the

capability and responsibility for providing on-orbit power sources for their own

segments, as well as power sharing, as required, to support assembly and ISS

operations for all International Partners.

The ROS and USOS Electrical Power Systems (EPSs) are responsible

for providing a safeguarded source of uninterrupted electrical power for ISS.

To accomplish this, the EPS must generate and store power, convert and

distribute power to users, protect both the system and users from electrical

hazards, and provide the means for controlling and monitoring system

performance. These functions are

performed by several pieces of interrelated ISS hardware/software, which are

each discussed in detail in the ISS Electrical Power System Training Manual

(TD9707). However, to provide the proper context for the detailed discussion, it

is helpful to take a “big picture” look at the EPS system, its responsibilities,

architecture, and components.

Note that the scope of this familiarization manual is the

Flight 8A configuration. At the 8A assembly stage, both the ROS and USOS EPSs

generally have sufficient power generation capability to meet their segment

power demands, although power transfer is performed, as required.

This manual focuses on the USOS EPS but includes descriptions of the ROS

EPS, in particular, noting the similarities and differences between the two

power systems.

After completing this section, you should be able to:

· Describe how the EPS architecture provides for power

generation, storage, distribution, conversion, and supporting functions

· Describe the EPS interfaces to other systems

· Identify differences and similarities between the ROS EPS

and USOS EPS

· Identify the primary methods of generating power for the

Flight 8A configuration.

3.3 USOS EPS Functional

Design

The USOS EPS is designed to be a distributed power system;

i.e., power is produced in localized areas and then distributed to various

modules. As illustrated in

Figure 3-1, this functional

design is similar to the process used by municipal electric utilities to provide

electrical power to users.

Figure 3-1. Analogy between

municipal electric utilities and ISS EPS

· High voltage power or “primary power” is generated in a

centralized power plant and distributed throughout the area via transmission

lines.

· Before power is delivered to users, the voltage is

stepped down by a transformer to the user required regulated voltage level.

· “Secondary power” (power transmitted at the user-required

voltage level) is distributed to nearby locations and is further divided and

routed by distribution boxes to provide electricity to many individual users.

An analogous process is used on ISS. USOS EPS design

incorporates modules (called Photovoltaic Modules (PVMs)) that are dedicated to

generating and storing power. These

modules or “power plants” provide two sources of primary power (~160 V dc)

called power channels. During both

insolation and eclipse, each power channel provides a continuous supply of power

for distribution throughout ISS.

Primary power is then converted to secondary power (~124 V dc) in proximity to

its intended users. From the converters, secondary power is distributed along a

variety of paths to individual ISS power users.

This two-level power system allows EPS to compensate for factors such as

line losses, hardware degradation, and solar array aging within the primary

power system while providing consistent secondary voltage for ISS users. Per

this distributed design, primary power is used when transmission over

significant distances is required and secondary power is for distribution

locally.

The distributed design of the USOS EPS architecture

provides for the incremental buildup of the power system during ISS assembly.

The PVMs are independent power plants that add to the primary power

production capability. The Secondary Power System, on the other hand, is a local

power network that is integrated into the trusses, modules, and racks of the ISS.

Thus, the Secondary Power System network expands with each ISS assembly stage to

provide new components with power access.

At Assembly Complete, there will be four PVMs (and eight

power channels), which are identified in

Figure 3-2.

Figure 3-2. ISS at assembly

complete

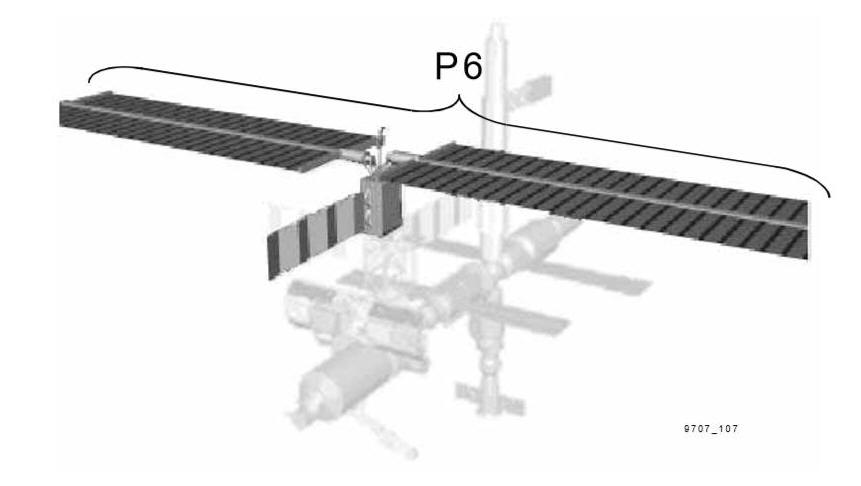

For the Flight 8A scope of this manual, all USOS EPS

primary power is provided by the P6 PVM. The P6 PVM arrives on Flight 4A.

As shown in Figure 3-3, the P6 PVM is

temporarily located on the Z1 truss until it is moved to its Assembly Complete

location on the lateral truss at Flight 13A (see

Figure 3-2). Secondary Power

System components are located on the P6 PVM, Z1 truss, S0 truss, Node 1, PMAs,

Airlock and Lab at Flight 8A.

From the previous description, five core functions can be

identified as necessary to achieve the function of the EPS:

· Generate primary power

· Store primary power

· Distribute primary power

· Convert primary to secondary power

· Distribute secondary power to users.

In addition, there are three support functions that must be

accomplished:

· Thermal control of EPS components

· Grounding of EPS components and ISS

· Managing and controlling the EPS components and

power/energy management.

These USOS EPS functions have been loosely grouped into

three main subsystems: Primary

Power System, Secondary Power System, and support systems.

The entire power system, except for grounding and control, are

illustrated in Figure 3-4.

The following sections briefly describe each of the three main

subsystems, as well as their functions and components.

Figure 3-4. USOS EPS schematic

The basic building block of the USOS EPS Primary

Power System architecture is the power channel, which is a group of hardware

components, beginning with a solar array, that are responsible for providing an

independent primary power source.

At this assembly stage, the entire Primary Power System can

be described in terms of a power channel as illustrated in

Figure 3-5.

The following components comprise a power channel:

· Solar Array Wing (SAW), including two Photovoltaic (PV)

blankets, the right and left blanket boxes, mast, and mast canister

· Sequential Shunt Unit (SSU)

· Beta Gimbal Assembly (BGA)

· Electronics Control Unit (ECU)

· Direct Current Switching Unit (DCSU)

· Three Battery Charge/Discharge Units (BCDUs)

· Three battery assemblies (Two-battery Orbital Replacement

Units (ORUs)/assembly).

Though Dc to Dc Converter Units (DDCUs) are generally

associated with the Secondary Power System, each power channel also includes a

DDCU to provide secondary power for IEA components.

Figure 3-5. USOS EPS power channel

A PVM contains all the components for two power channels;

i.e., two sets of PV blankets (see Figure 3-3)

and correspondingly two identical sets of power channel hardware.

This hardware is

mounted on the Integrated Equipment Assembly (IEA).

The IEA, indicated in

Figure 3-6, is the truss framework that structurally and electrically

integrates the PVM for on-orbit operations. Power channel and support equipment

for the two respective power channels are mounted on the “top” and “bottom” of

the IEA. The IEA structure also

provides integrated cold plates and coolant loops for use by the Photovoltaic

Thermal Control System (PVTCS), which is dedicated to removing excess heat from

IEA hardware. The thermal radiator

for PVTCS can be seen in its deployed state in

Figure 3-6.

Figure

3-6. Integrated equipment assembly

3.4.1.1 Primary Power Generation

Power generation onboard ISS includes conversion of solar

energy to electrical energy, as well as the regulation of that electrical

energy. The power generation

function is accomplished by the PV blankets and structural support hardware

(blanket boxes, mast, mast canister), BGA, ECU; and SSU.

The PV blanket is a collection of PV cells wired in series

providing the large light collecting surface required to meet ISS power needs.

A pair of blankets (left and right) constitutes a PV array.

The PV blankets are supported by blanket boxes (which also serve to house

and protect the blankets for launch).

Figure 3-7 shows the

blankets in a partially deployed state.

The blanket boxes are rigidly attached to the mast canister which

provides the housing and extension/retraction mechanisms for the mast that are

used to support the deployed blankets.

In its stowed configuration, the mast is collapsed inside the mast

canister; for deployment, the mast extends to the deploy the array.

The mast, along with the blanket and containment boxes and other

associated hardware, provides the ability to rigidize the deployed PV blankets.

Collectively, the left and right PV blanket and containment boxes, and the mast

canister with mast, are referred to as the Solar Array Wing (SAW).

Figure 3-7. Partially deployed solar array wing

In order to maximize the collection of usable solar energy

in an orbiting vehicle, the PV arrays must be oriented to face the Sun, or more

specifically, to maximize the planar projection of the collection device

relative to the Sun. At Flight 8A,

the Beta Gimbal Assembly (BGA), indicated in

Figure 3-6, is the hardware

providing array orientation. The

BGA provides for rotation of the PV array around its long axis as required to

track the Sun and maximize solar array power production.

The Electronic Control Unit (ECU) located on the BGA is the

command and control link for the power generation function.

The ECU provides power and control for extension and retraction of the

solar array mast, latching and unlatching of the blanket boxes, BGA rotation,

and BGA latching.

Regulation of the array output voltage is required because

of the performance characteristics of PV cells; i.e., output voltage is a

function of the load placed on the cells, resulting in a varying power source

(see Section 2 for further details).

To accomplish this, the Sequential Shunt Unit (SSU) receives power

directly from the PV array and maintains output voltage within a specified range

of 130 V dc to 180 V dc (referred to as “primary power voltage”).

By design, the SSU provides a consistent source of power (typically ~160

V dc), based upon a programmable setpoint.

All EPS equipment or components that use primary power are designed to

accept power within this wide voltage range.

The rationale for regulating power within such a wide range is to account

for:

· Line losses resulting from transferring power across

significant distances on ISS

· Flexibility in regulation to account for downstream

hardware degradation

· Flexibility in regulation to account for hardware aging

(i.e., solar cell aging results in a significant drop in peak output voltage)

· Output voltage of solar cells that vary significantly as

a function of load.

Thus, the SSU considers the above factors, stabilizes the

SAW output voltage based upon a voltage setpoint (typically ~160 V dc) and

relies upon the Secondary Power System to provide consistent, tightly regulated

~124 V dc secondary power to users for the life of the ISS.

The orientation of the energy collection devices and the

regulation of their output voltage are only critical during insolation.

The next segment discusses the power storage function which is required

to provide power during eclipse.

The power storage function is performed by batteries and

BCDUs. The actual storage devices

are Nickel Hydrogen (NiH 2) battery assemblies, each having their own BCDU to

control their State of Charge (SOC).

A battery assembly consists of two battery ORUs connected to a single

BCDU. As seen in Figure 3-5, there

are three battery assemblies and three BCDUs associated with each power channel.

As the name of this function and its associated hardware implies, it is

responsible for storing power throughout the entire orbit. During insolation,

array power is used to charge the batteries.

During eclipse, a portion of the stored battery power is discharged to

supply the ISS. Stored power may

also be used to supplement the power generation function during insolation;

i.e., to satisfy a temporary high power load on the EPS or to supply power in

case there is a failure within the power generation function (including failure

of the SAW orientation function).

With a full complement of batteries (three battery

assemblies/power channel), the storage system is designed to require only a 35

percent depth of discharge to supply the nominal ISS power needs during the

period of orbital eclipse. Given

that the ISS is not exceeding its planned energy consumption, the batteries can

then be fully charged during a single period of insolation.

If the power generation function were to fail, the batteries can supply

power for one complete orbit following a period of orbital eclipse with a

reduced ISS power consumption rate.

The charge and discharge profiles must be carefully controlled to maximize the

life of each of the batteries. The battery SOC determines the recommended

charging profiles used by the BCDUs to regulate the charging of the batteries.

It is important to emphasize that power storage is a

function of the Primary Power System and occurs before the primary power is

converted into secondary power.

This permits a more centralized power storage function (all accomplished on the

PVMs) versus a decentralized power storage function as part of every secondary

power circuit. This centralized

approach results in decreased weight and cost to perform the power storage

function.

The power generation and power storage functions provide

power sources for the Primary Power System, but power flow must be coordinated

between the arrays and batteries, as well as to other components on the IEA and

on to the ISS. This interface is

provided by the power distribution components.

3.4.1.3 Primary

Power Distribution

Primary power distribution for a power channel is the

function of the DCSU. Using a

network of high power switches called Remote Bus Isolators (RBIs), the DCSU

interconnects arrays and batteries to the primary power distribution bus.

During insolation, the DCSU routes power from the arrays to the ISS, as

well as to the BCDUs for battery charging.

During eclipse, the DCSU routes battery power to the ISS to satisfy power

demands. In addition to primary

power distribution, the DCSU has the additional responsibility for routing

secondary power to components on the PVM (e.g., the ECU and other support

components). Note that while the P6

PVM is located on the Z1 truss, secondary power produced on the IEA is also

routed directly to the Z1 truss for distribution.

This secondary power is provided by the DDCU located on the IEA. The DDCU

receives primary power from the DCSU, converts into secondary power and sends it

back to Remote Power Controller Modules (RPCMs) (see next section) for

distribution. The RPCMs are housed

within the DCSU as shown in Figure 3-5.

While the DCSU handles power distribution on the IEA, the

BGA provides for the transmission of primary power from the PV array to the IEA.

The BGA also provides for transmission of secondary power to the ECU.

Although it has no switches to control the flow of power, the BGA

incorporates a roll-ring design to provide conduits for power (and data), while

allowing a continuous 360° rotation.

The DCSU provides one output of primary power from a power

channel. While the P6 PVM is

located on the Z1 truss, further distribution of primary power from power

channels 2B and 4B to various areas of the ISS is accomplished by Integrated

Diode Assemblies (IDAs) located on the Z1 truss (shown

in Figure 3-5). From the IDAs,

primary power is input to the Secondary Power System for conversion and

distribution of power to users. The

Secondary Power System is the subject of the next section.

The Secondary Power System is illustrated in

Figure 3-8.

The first step in the local power distribution is the conversion from

primary power (~160 V dc) to secondary power (~124 V dc). Power conversion

occurs in various areas throughout the ISS, within pressurized modules, on truss

segments, as well as on the IEA, i.e., near wherever users require secondary

power. After conversion, secondary power is distributed through a network of

power distribution assemblies. The

active components within these distribution boxes are remotely commanded

switches that control and monitor the flow of power through the network to

individual users, such as systems, payloads, crew equipment, EPS components,

etc.

Figure 3-8.

USOS secondary power system

3.4.2.1 Secondary Power Conversion

The secondary power conversion function uses one type of

ORU, the DDCU. As the name implies,

the DDCU is responsible for dc power conversion, in this case, primary power

into secondary power using a transformer.

Each DDCU has one primary power input and one secondary power output.

As discussed earlier, the primary power voltage is typically ~160 V dc

but can vary over a wide range, while the output is specified to be ~124 V dc,

which is the prescribed voltage for all users of the Secondary Power System.

If any other voltage level is required by user loads, (e.g., payloads or

crew equipment) then it is the responsibility of the user to perform the

conversion from ~ 124 V dc to the required voltage.

3.4.2.2 Secondary Power Distribution

The workhorse of the secondary power distribution system is

the RPCM, an ORU, which contains solid-state or electromechanical relays, known

as Remote Power Controllers (RPCs). These switches can be remotely commanded to

control the flow of power through the distribution network and to the users.

There are different types of RPCMs, resulting from varying numbers of

RPCs and varying power ratings. As

shown in Figure 3-8, secondary

power originates in a DDCU and is then distributed through a network of ORUs

called Secondary Power Distribution Assemblies (SPDAs) and Remote Power

Distribution Assemblies (RPDAs).

SPDAs and RPDAs are essentially housings that contain one or more RPCMs; the

designation, either SPDA or RPDA, refers to the level of hierarchy within the

distribution system As a general

rule, the hierarchy dictates that DDCUs feed power to SPDAs, which either

provide power to one or more user loads or RPDAs.

RPDAs, in turn, feed power to one or more user loads.

Note that RPCMs have only one power input; thus, if power is lost at any

level of the Secondary Power System, all downstream user loads will be without

power. As mentioned previously,

there is no redundancy in the Secondary Power System; rather, redundancy is a

function of the user’s loads. For

example, a critical user load may be able to select between two input power

sources that use different power channels and thus different secondary power

paths.

As with DDCUs, SPDAs and RPDAs may be located internally or

externally. Depending on their

specific location, SPDAs and RPDAs may interface with EETCS or use heat pipes

where EETCS is not available.

Recall that RPCMs are also located within the DCSU on the IEAs to provide

distribution and control of secondary power to power channel components, as

required.

In addition to functions, such as power production,

storage, conversion, and distribution, other supporting functions must be

incorporated into the architecture to maintain the USOS EPS.

USOS EPS Photovoltaic Modules (PVMs) are designed with

their own Photovoltaic Thermal Control System (PVTCS).

This is necessary because at Assembly Complete, all PVMs are separated

from the ISS by 360° rotating Solar Alpha Rotary Joints (SARJs) which pass power

and data, but not fluids. Thus,

PVMs cannot interface with the ISS Thermal Control System (TCS).

Each power channel has its own independent PVTCS consisting of one Pump

and Flow Control Subassembly (PFCS) ORU and coldplates, coolant lines, and

ammonia coolant which are integrated into the IEA.

PVTCS also includes one Photovoltaic Radiator (PVR) per IEA, shown in

Figure 3-3, which is shared by the two power

channels on a PVM. It is important

to note that although the two PVTCS cooling loops share a common PVR, the

cooling lines do not intersect and thus the PVTCS operate independently.

Another important factor in the design of the EPS is the

grounding scheme to minimize arcing and shock hazards.

The grounding function is incorporated in the Single Point Ground (SPG)

architecture that maintains all components on the ISS at a common potential.

SPG refers to grounding such that all the structures and components

within the USOS are electrically tied to a common point (the metal

infrastructure of the ISS), minimizing electrical shock hazards to the crew and

equipment. Another potential shock

hazard exists when equipment such as personal computers are connected to Utility

Outlet Panels (UOPs). To eliminate

this hazard, Ground Fault Interrupters (GFIs) are installed on all utility

outlet panels to detect short circuits and disconnect equipment from the power

source.

Although the SPG architecture maintains all components of

the USOS EPS at a common potential, this potential may not correspond to the

surrounding space environment. As

it turns out, the potential difference between the ISS structure and the plasma

environment in orbit could be as much as ~140 V dc during insolation.

This difference in potential can result in microarcing between the space

environment and the ISS structure, potentially damaging the arrays or thermal

coating that covers the ISS. To

minimize this potential difference, Plasma Contactor Units (PCUs) located on the

Z1 truss (one operational and one backup) generate plasma from Xenon gas and

emit a stream of electrons into space.

This electron emission results in a “grounding-strap” that effectively

grounds the ISS to the space environment, minimizing the potential difference as

well as related hazards to the ISS and crew.

Operating behind all of these before-mentioned functions,

four tiers of command and control units/applications work to monitor and control

the operation of the USOS EPS.

Command and control of the USOS EPS is provided by software applications and

hardware which provides system monitoring and reconfiguration capabilities from

both onboard and the ground. The

onboard capability allows the crew to determine system status and provides any

required reconfiguration for systems operations.

Ground control and monitoring is required to support ISS EPS operations,

analysis, and planning.

Figure 3-9. Structure of EPS

command and control tiered architecture

The tier structure and example responsibilities of the

command and control ORUs are illustrated in

Figure 3-9.

Command and control functions for the top three tiers are performed by

computers or Multiplexer/Demultiplexers (MDMs).

Tier 1 control is a function of the Command and Control (C&C) MDM

(located in the Lab) through which both crew and ground interface all command

and control functions. Most of the

EPS functionality at the Tier 2 level, is performed by the Power Management

Control Unit (two located in the Lab, one backup) and the Node 1 MDM, although

other MDMs may have control of particular DDCUs and RPCMs.

At this assembly stage, the Tier 3 Node 1 MDM’s have Tier 2

responsibilities, including controlling the Tier 3 Photovoltaic Control Units

(PVCUs) located on the P6 PVM.

Although there is one PVCU per power channel (PVCU-2B, PVCU-4B), one PVCU

controls the operations of both power channels on the PVM with the other as

backup. Note that the MDMs are

generally in close proximity to the equipment for which they are responsible.

Tier IV consists of firmware controllers responsible for controlling

component functions and providing telemetry to higher tiers.

3.4.4 USOS EPS Redundancy and

System Protection

Thus far, the architecture of the USOS EPS has been

discussed in terms of how power is provided to ISS users.

But equally important functions of the system architecture are redundancy

and fault protection.

Each of the power channels are preconfigured to supply

power for particular ISS loads; however, to provide for power source redundancy,

the assembly complete design provides for rerouting (i.e., cross-strapping)

primary power between various power channels, as necessary.

At Assembly Complete, the USOS EPS will have four PVMs containing eight

SAWs and correspondingly eight power channels (shown in

Figure 3-2) with full

cross-strapping capability. However, through Flight 8A, there is only one PVM

and no cross-strapping capability (refer to Section 2).

It is important to note that only primary power can be cross-strapped.

Once power is converted into secondary power, power flow through the

distribution network cannot be rerouted. As a result, if there is a failure

within the Secondary Power System, there is no redundancy, and the entire

downstream path from the failure is unpowered.

Instead, redundancy is generally determined by user loads.

Examples are:

· The component may swap between multiple power input

sources

· Multiple components perform the same function; thus, the

responsibilities of one component are assumed by another

· Multiple components work

together to perform a function with the loss of a component, resulting in

degraded operational capabilities.

Details concerning hardware redundancy within EPS

components is discussed in Section 2.

System protection encompasses the architecture’s ability to

detect that a fault condition has occurred, confine the fault to prevent

damaging connecting components, and execute an appropriate recovery process to

restore functionality, if possible.

This process is usually referred to as Fault Detection, Isolation, and Recovery

(FDIR). For example, upon detection

of a fault, components can be isolated, thereby preventing propagation of

faults. In response to overcurrent

conditions, the architecture is designed such that each downstream circuit

protection device is set to a lower current rating and responds more quickly

than the protection device directly upstream. This ensures that electrical

faults or “shorts” in the System do not propagate toward the power source.

Another function of the architecture’s system-protection shuts down the

production of power when array output voltage drops below a specified

lower-limit threshold. This

prevents the Photovoltaic (PV) cells from operating in low-voltage, high-current

applications, causing cell overheating.

In summary, all the various implementations of system-protection work

together to isolate faults or shorts at the lowest level.

This approach minimizes impacts to the users of the EPS and also protects

the EPS from complete failure from low-level faults.

More details concerning redundancy, system protection, and

FDIR are contained in the description of individual components in the ISS

Electrical Power System Training Manual.

The following section describes the USOS EPS interfaces

with other systems and power sources.

In addition to the power sources inherent to the USOS EPS,

other power sources from the ROS, including the FGB and SM, as well as the

Shuttle, are required to support various phases of assembly and ISS operations.

Thus, power interfaces are required to allow transferring power among the

USOS, the ROS, and the Shuttle.

3.5.1.1 Russian -

American Power Interface

According to operational agreements, ROS power will support

USOS operations early in the Assembly Phase.

However, power conversion is required because the user-voltage level

required by the USOS is ~124 V dc and the FGB EPS provides power at ~28 V dc.

This function is accomplished by the Russian-to-American Converter Unit

(RACU). Similarly, per operational

agreements, USOS will provide power to the ROS, which also requires conversion.

The American-to-Russian Converter Unit (ARCU) transforms the ~124 V dc

power produced by the USOS EPS into the ~28 V dc power for use by the FGB EPS.

Both the ARCUs and RACUs, located on the FGB and SM, are under Russian

command authority.

3.5.1.2 Shuttle Power Conversion

The USOS EPS will also be supported by the Shuttle when it

is docked to the ISS. Although the

Shuttle power system generates ~28 V dc, Assembly Power Converter Units (APCUs)

located in the Shuttle payload bay can provide either primary (~140 V dc) or

secondary (~124 V dc) voltage per the requirements for the particular mission.

However, the voltage level is reconfigured on the ground and cannot be

changed on orbit. For example, the

APCU is configured to output primary power for Flight 4A to support power

channel startup operations but configured to output secondary power for the MPLM

on its Shuttle flights. Commanding

of the APCU (on/off) is performed by the Shuttle crew on orbit.

In addition to power interfaces, USOS EPS has interfaces

with other systems, both to provide power or receive necessary data or services.

Recalling the discussion of the Secondary Power System, note that all

systems that require power from USOS EPS must interface with the Secondary Power

System and a specific RPC (except for some EPS components that use primary

power). The following sections

describe the USOS EPS interfaces for receiving data or services from USOS

systems.

3.5.2.1 Guidance, Navigation and Control

To orient the arrays, the Guidance, Navigation and Control

(GNC) MDM broadcasts target angles for the BGAs.

This data is routed through the Node 1 MDM to the PVCU.

The PVCU then commands the BGA to the proper orientation.

3.5.2.2 Command and Data Handling

Command and Data Handling (CDH) provides all MDMs, data

processors, and data buses required for the execution environment of the EPS

software applications providing the control and monitoring functions.

Supporting the software execution environment not only includes the data

processing, but also the data communications.

Data communications includes the transmission of commands, status, and

data parameters required to monitor and control the EPS.

3.5.2.3 Thermal Control System

Where possible, USOS EPS components interface with the ISS

TCS (ETCS or EETCS for external components and ITCS for internal components) for

thermal control. However, on the

PVMs and the Z1 truss, ISS TCS is not available.

Consequently, PVMs use PVTCS for active thermal control of IEA

components, and DDCUs, SPDAs, and RPDAs located on the Z1 truss use heat pipes

for passive cooling.

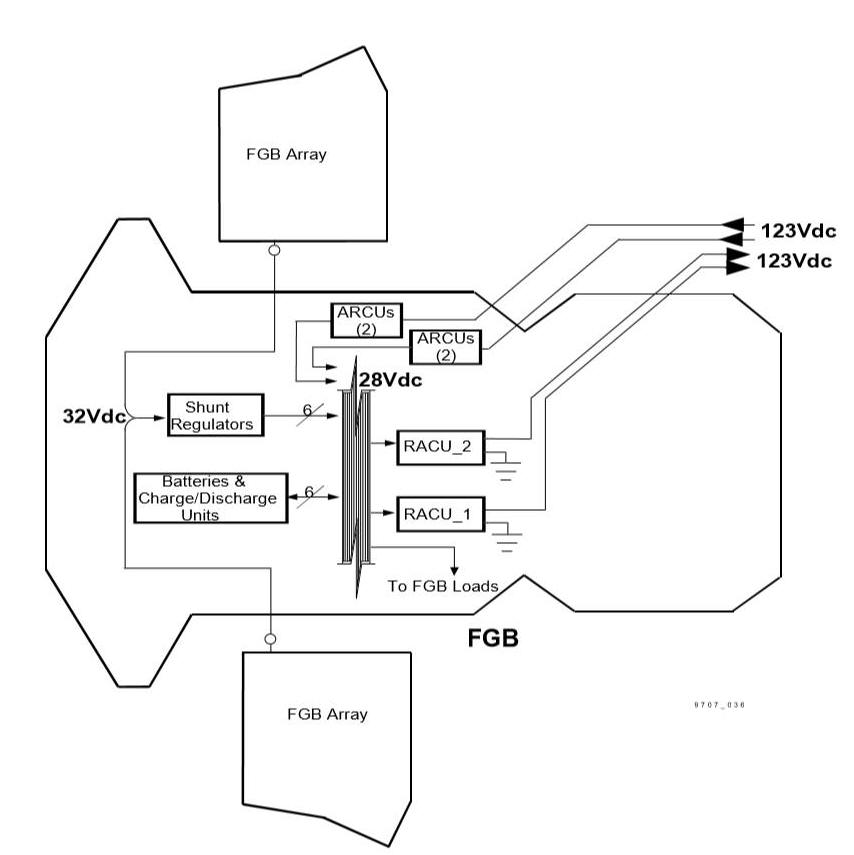

3.6 Comparison between USOS

and ROS EPS

For comparison purposes, consider

Figure 3-10, which illustrates

the EPS of the FGB. (FGB is used as

a representative example of ROS EPS architecture.).

In contrast to the USOS EPS distributed system design, the FGB uses a

localized architecture. Instead of

producing power in PVMs and distributing that power throughout multiple modules

as in USOS EPS, the FGB and SM have self-contained EPS within each module (i.e.,

the FGB and SM modules produce, store, and consume their own power).

However, the power system components are similar: solar arrays, array

output regulators, batteries, charge/discharge units, and a distribution system.

Furthermore, the voltage produced by the Russian arrays is converted to a lower

user voltage level (32 V dc to 28 V dc), although this differs from the USOS EPS

voltage levels (160 V dc to 124 V dc).

ARCUs and RACUs provide the power interface between the USOS and ROS EPS

by compensating for the different voltage levels.

Another less apparent difference is that the ROS EPS uses a floating

ground rather than the SPG, as in the USOS EPS.

For the floating ground, equipment chassis are connected to the ISS

infrastructure. However, individual

components may not be; thus, all components may not be at a common potential.

Figure 3-10.

FGB electrical system drawing

A common question in regard to system design involves the

choice of the USOS operating voltage level of ~124 V dc compared with the more

common ~ 28 V dc currently used on the Shuttle, FGB, and the MIR space station.

Part of the reason lies in the scope of the ISS, including the associated

power requirements and the use of a distributed EPS architecture. Considering

that power is a function of voltage and current, at low voltages, high power

requires large currents. Large

currents require heavy, thick conductors and have associated line losses. Use of

a higher voltage level (near the USOS commercial standard 120 V ac) addresses

the issues of cost, weight, and power loss for the USOS EPS.

Both the ROS and USOS EPS have the capability and

responsibility for providing continuous electrical power to the ISS.

Although the ROS and USOS EPS are similar in functionality, the FGB and

SM are designed with self-contained EPS, while the USOS uses a distributed

approach. The USOS EPS continuously generates primary power on PVMs and

transmits it into the vicinity of the power user, converts into secondary power,

and distributes power to each local user.

On Flight 8A, shown in Figure

3-11, USOS power production capability is provided by the P6 PVM.

During this assembly stage, ISS power is provided by P6 arrays, FGB

arrays, and SM arrays. Note that

APCU power is also available when the Shuttle is docked to the ISS.

Figure 3-11. ISS at 8A

Table 3-1 provides a summary of the functions and components discussed in

this overview that accomplishes the USOS EPS function.

It is important to emphasize the two areas not addressed in this table:

· System protection, which is distributed across the USOS

EPS in the form of software and hardware sensing of fault conditions and

reactions to isolate faults and minimize system impacts

· System grounding design, which ties all components to a

common potential.

Through the scope of this manual, the functions of the

Primary Power System are accomplished by power channel components.

Through the Flight 4A-12A period, all USOS EPS power is provided by two

power channels on the P6 PVM. This

power is transmitted directly to Secondary Power System components throughout

the USOS segment, where it is converted to the proper voltage level and

distributed to ISS users.

Table 3-1. USOS EPS

components at flight 8A

*Four MBSUs are located on the S0 truss segment by Flight

8A but not integrated into the USOS EPS.

Additional power sources from the ROS and Shuttle are

necessary for the assembly and operation of the ISS.

These power sharing interfaces employ converters to compensate for

voltage differences between the following electrical systems:

· APCU for interfacing between USOS EPS and Shuttle

· ARCU and RACU for interfacing between USOS EPS and ROS

EPS