6 Environmental Control and

Life Support System Overview

6 Environmental Control and

Life Support System Overview

Figure 6-1. ECLSS Subsystem interfaces at

Flight 8A

6.3.1 Atmosphere Control and

Supply

Figure 6-2, the ECLSS USOS Atmosphere

Control and Supply Subsystem

6.3.1.1

USOS Atmosphere Supply, Distribution, and Control

6.3.1.3 Pressure Equalization

Between Modules

6.3.1.4 Additional Atmosphere

Control and Supply Capabilities at Assembly Complete

6.3.2 Atmosphere

Revitalization

Figure

6-3 ECLSS Functional Overview USOS Atmosphere Revitalization Subsystem and its

Interfaces

6.3.2.1 Major Constituent

Monitoring

6.3.2.2 Carbon Dioxide

Removal

6.3.2.3 Trace Contaminant

Control

6.3.2.4 Additional Atmosphere

Revitalization Capabilities at Assembly Complete

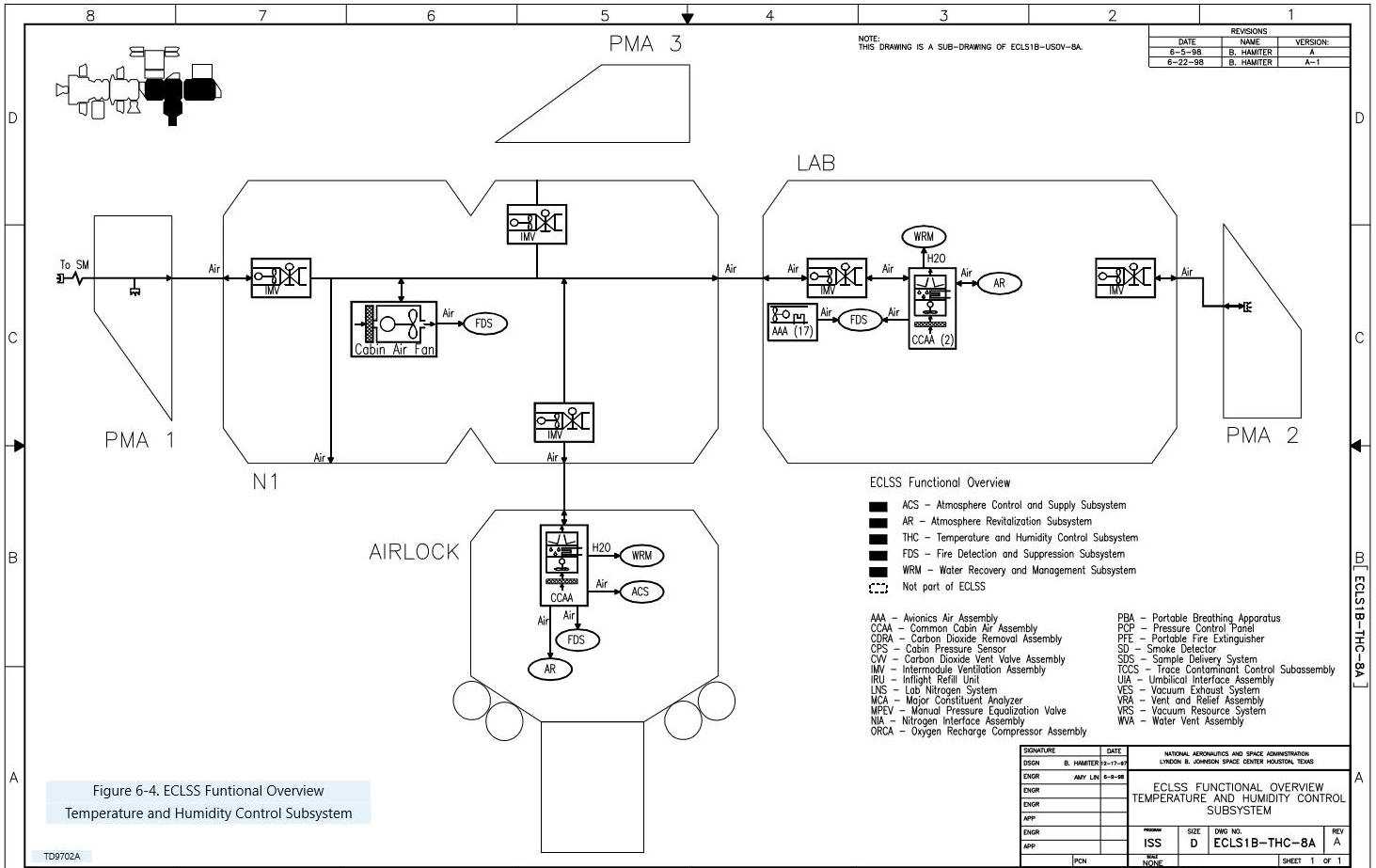

6.3.3 Temperature and

Humidity Control

Figure 6-4 ECLSS Functional Overview

Temperature and Humidity Control Subsystem

6.3.3.2 Intramodule

Ventilation

6.3.3.3 Intermodule

Ventilation

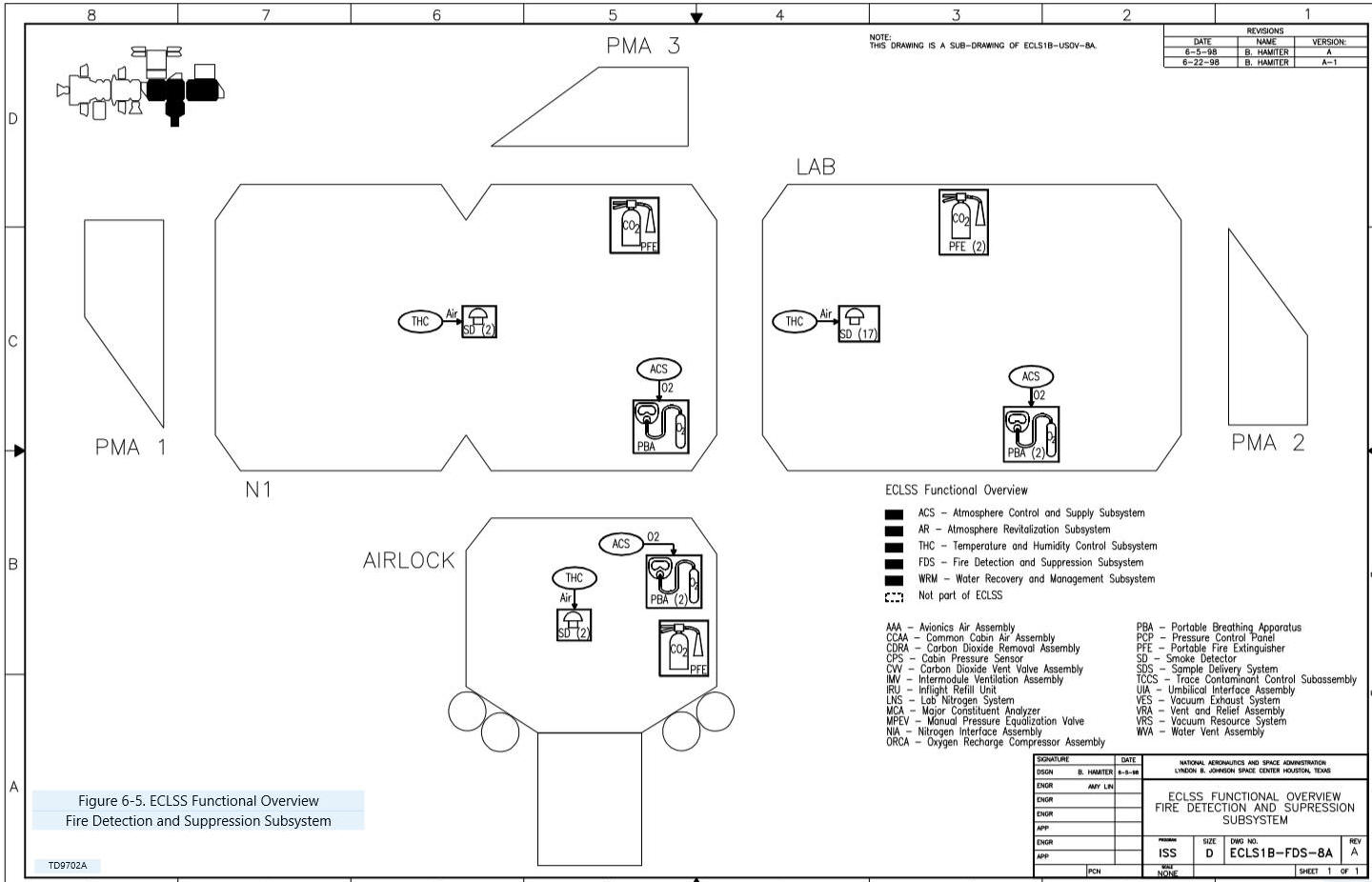

6.3.4 Fire Detection and

Suppression

Figure 6-5, ECLSS Functional Overview

Fire Detection and Suppression Subsystem

6.3.4.4 Supplemental Oxygen

Supply

6.3.4.5 Additional Fire

Detection and Suppression Capabilities at Assembly Complete

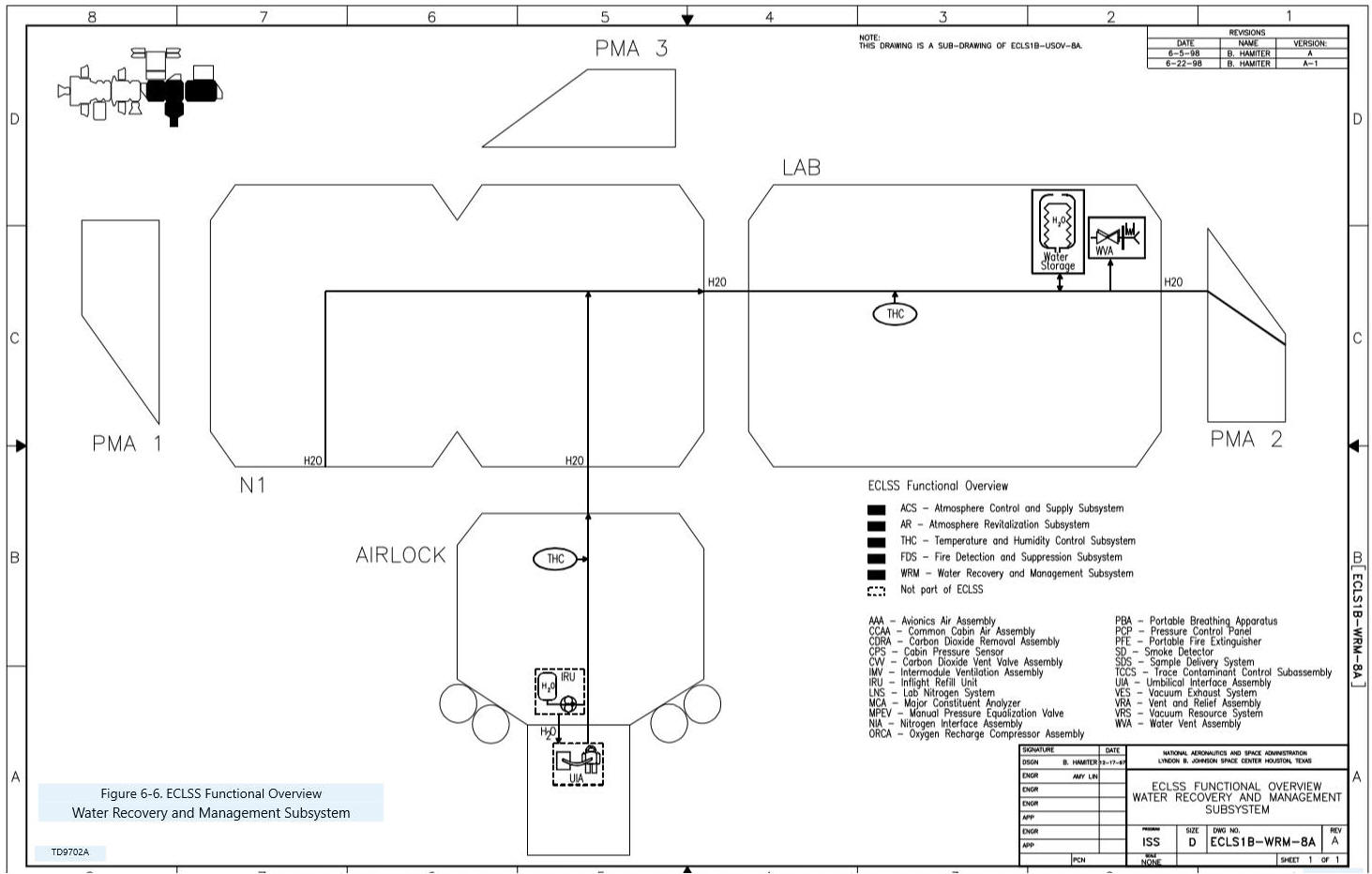

6.3.5 Water Recovery and

Management

Figure 6-6, ECLSS Functional Overview

Water Recovery and Management Subsystem

6.3.5.1 ROS Water Recovery

and Management Overview

6.3.5.2 USOS Water Recovery

and Management

6.3.5.3 Additional Water

Recovery and Management Capabilities at Assembly Complete

Figure 6-7. ECLSS interfaces at Flight 8A

6.5.1 Flight 1A/R -

Functional Cargo Block

6.5.3 Flight 1R - Service

Module

6.6.1 ECLSS Purpose and

Functions

6.6.2 Subsystem Names and

Functions

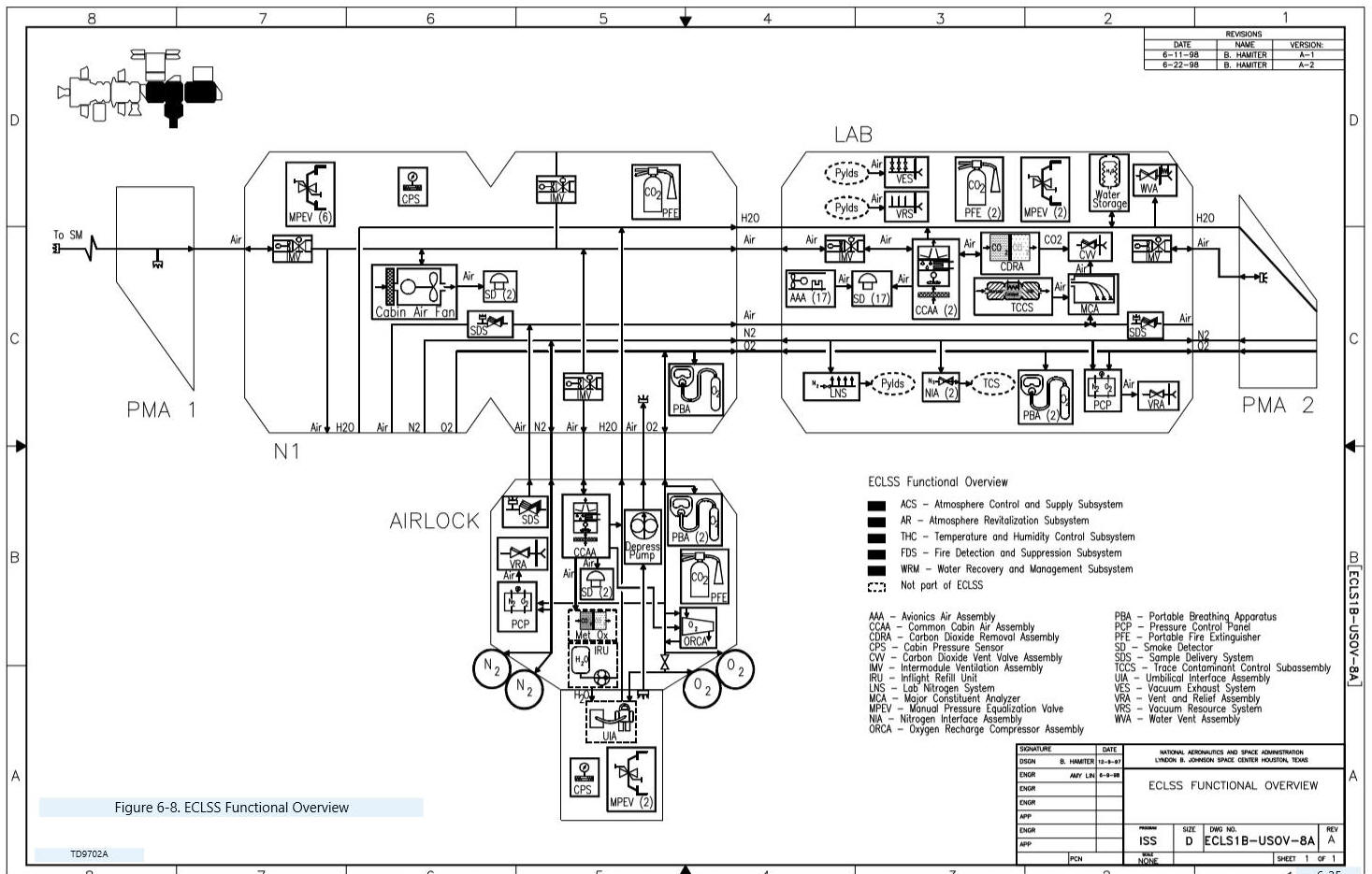

Figure 6-8 shows how all the components

of the subsystems interact with each other.

6 Environmental Control and

Life Support System Overview

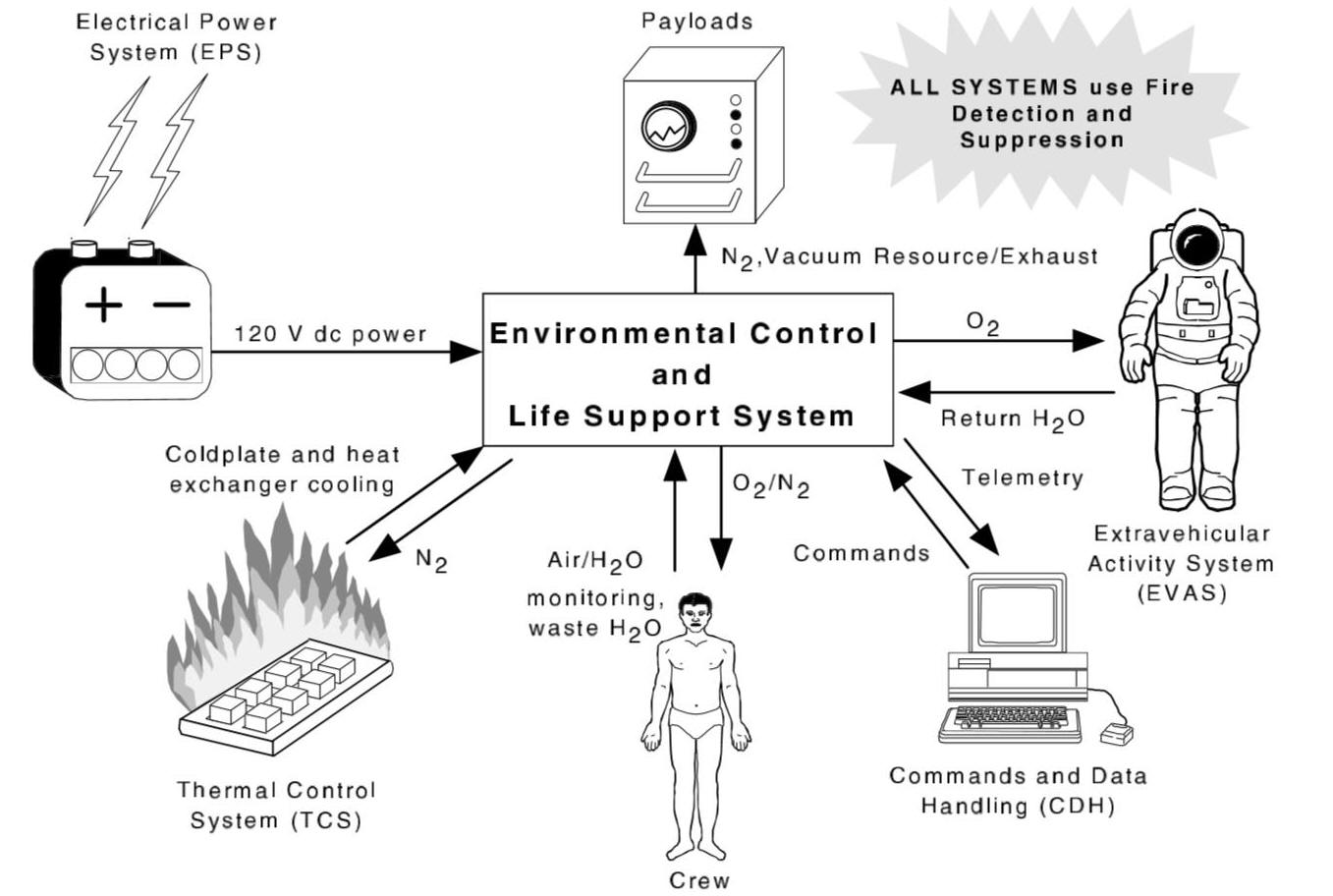

The Environmental Control and Life Support System (ECLSS)

maintains a pressurized habitable environment, provides water recovery and

storage, and provides fire detection and suppression within the International

Space Station (ISS). This segment

includes an overview of ECLSS and its component subsystems.

It also describes the relations between subsystems, and between ECLSS and

other Station systems.

After completing this section, you should be able to:

· Describe the major functions provided by ECLSS and each

of its subsystems

· Identify major ECLSS hardware components and state their

function and general functional redundancies

· Identify major ECLSS functional dependencies on the

Thermal Control System, Electrical Power System, and Command and Data Handling

System

· Identify major functional support provided by ECLSS for

the Thermal Control System, Payloads, Crew Health Care System, and

Extravehicular Activity System

· Describe major responsibilities and milestones of the

United States Orbital Segment (USOS) and Russian Orbital Segment (ROS) through

8A, as well as the USOS added capabilities at Assembly Complete.

The Environmental Control and Life Support System (ECLSS)

provides a pressurized and habitable environment within the Space Station by

supplying correct amounts of oxygen and nitrogen, controlling the temperature

and humidity, removing carbon dioxide and other atmospheric contaminants, and

monitoring the atmosphere for the presence of combustion products, and major

constituent proportions. The system

also collects, processes, and stores water and waste used and produced by the

crewmembers, and provides fire detection, suppression, and crew safety

equipment.

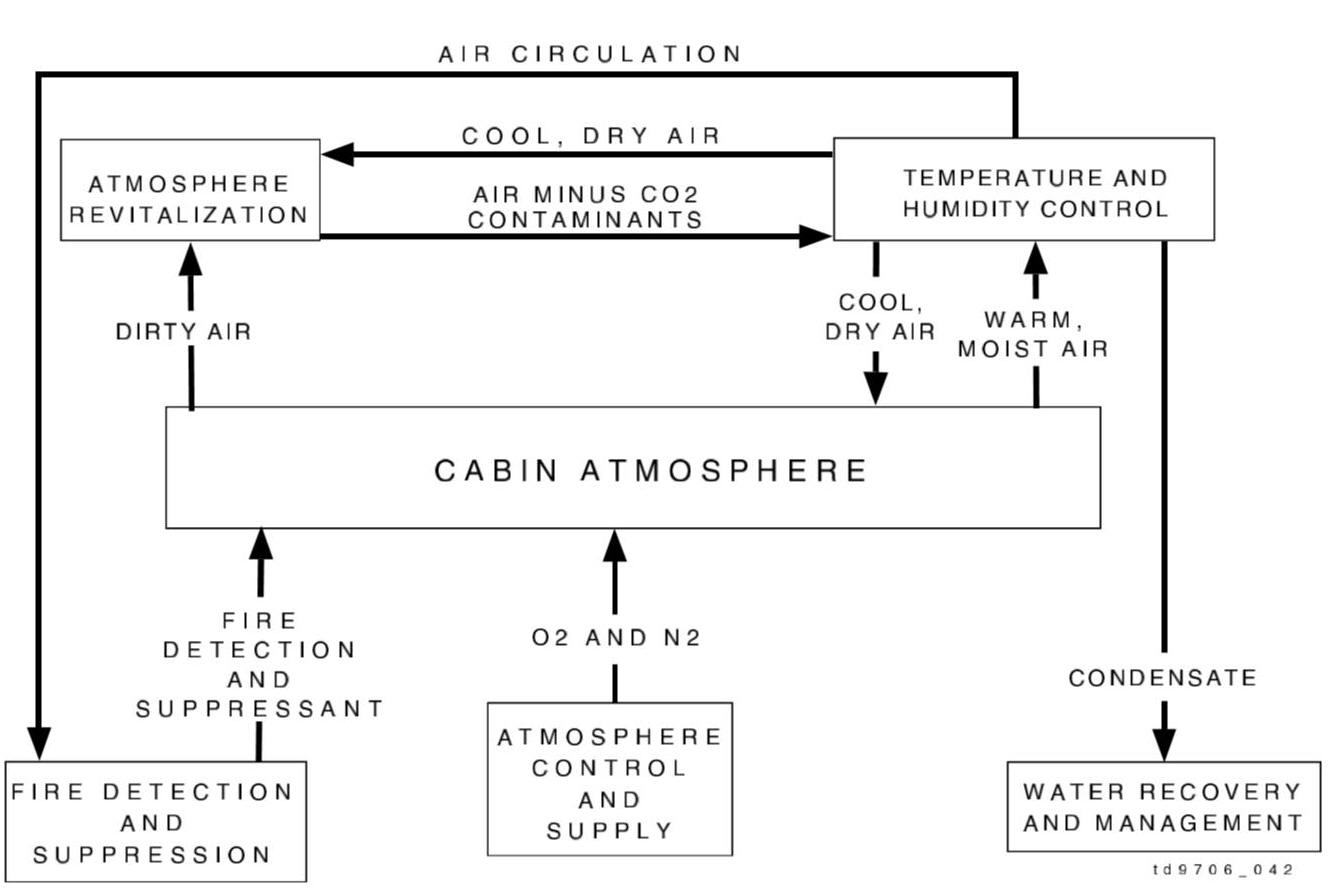

The general functions of the five major subsystems of USOS

ECLSS at Flight 8A are shown in

Figure 6-1. As illustrated, the

primary ECLSS concern, whether directly or indirectly, is with the ISS

atmosphere. This section of the ISS

Familiarization Manual presents ECLSS through its five subsystems:

Atmosphere Control and Supply, Atmosphere Revitalization, Temperature and

Humidity Control, Fire Detection and Suppression, and Water Recovery and

Management.

Figure 6-1. ECLSS Subsystem

interfaces at Flight 8A

6.3.1 Atmosphere Control and

Supply

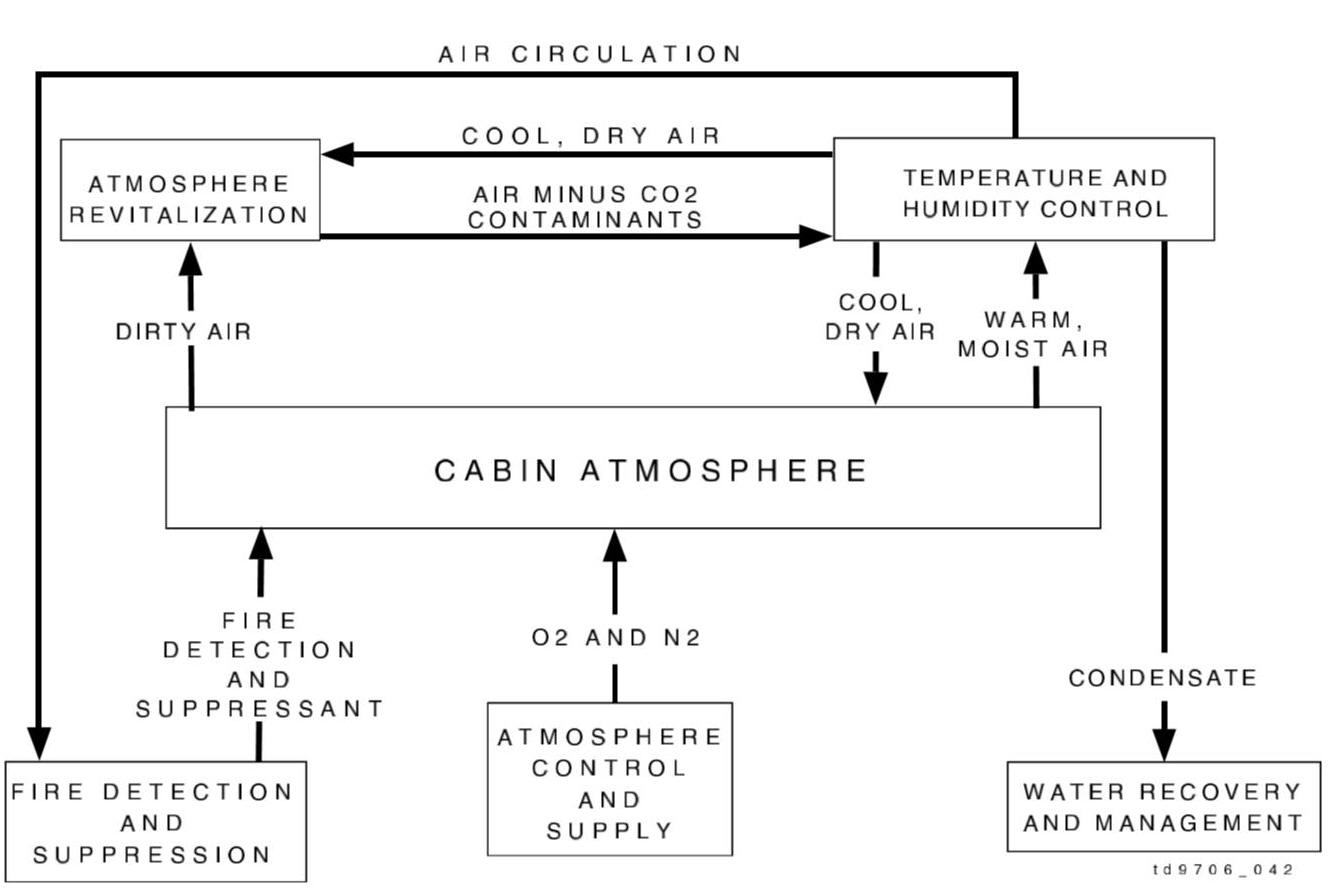

In Figure 6-2,

the USOS Atmosphere Control and Supply Subsystem and its interfaces are

illustrated for a Flight 8A configuration.

This subsystem provides oxygen and nitrogen to maintain the Space Station

atmosphere at the correct pressure and composition for human habitation.

The Atmosphere Control and Supply Subsystem also provides gas support to

various users on the Station, as well as pressure equalization and

depressurization capabilities.

Figure 6-2, the ECLSS USOS

Atmosphere Control and Supply Subsystem

The Russian Orbital Segment (ROS) has primary

responsibility for atmosphere control and supply functions at the Flight 8A

configuration. The Progress

resupply vehicle is outfitted with tanks that can be filled with either

nitrogen, air, or oxygen. These

tanks are manually opened by the crew if the cabin pressure is low.

Oxygen for the Station is primarily supplied by an oxygen generator

called the Elektron, which electrolyzes water into hydrogen and oxygen.

Additional oxygen can be provided by a Solid Fuel Oxygen Generator that

uses chemical cartridges to produce oxygen in an exothermic reaction.

6.3.1.1

USOS Atmosphere Supply, Distribution,

and Control

The oxygen and nitrogen gases used by the USOS Atmosphere

Control and Supply Subsystem are provided through the supply, distribution, and

control portions of the subsystem.

Four highpressure gas tanks, two of nitrogen and two of oxygen, are stored on

the exterior of the Airlock. The gases are distributed to the various users by a

plumbed system running throughout the USOS.

Another system of high-pressure plumbing allows the tanks to be recharged

by the Shuttle. An oxygen

compressor housed in the Airlock enables the oxygen tanks to be fully recharged

because the Shuttle does not store oxygen at a high enough pressure to fully

recharge the tanks. Empty tanks can

also be replaced with full tanks as a second resupply option.

The Pressure Control Assembly monitors atmospheric

pressures, controls the introduction of nitrogen and oxygen into the cabin

atmosphere, and provides the means to depressurize Station volumes if required.

The depressurization function is used in standard operations to relieve

atmospheric overpressure, and in emergencies to vent hazardous contaminants

overboard or as a last resort to extinguish a fire.

The Atmosphere Control and Supply Subsystem provides gas

support to several users on the Station besides the atmosphere.

Nitrogen is used to pressurize the Internal Thermal Control System

accumulators and to calibrate the Crew Health Care System Volatile Organic

Analyzer. The biggest users of nitrogen resources are the Payloads.

A minor subsystem of ECLSS, the Vacuum System, is included here because

its Payload support functions are similar to those of the Atmosphere Control and

Supply Subsystem. The nitrogen

provided to payload user via the vacuum system has vacuum resource and exhaust

capabilities. Oxygen is provided

for Extravehicular Activities (EVAs) and to the Fire Detection and Suppression

Subsystem Portable Breathing Apparatus (PBA).

The Airlock Depressurization Pump also supports normal EVA activities by

pumping most of the Crew Lock air into Node 1 before the crew egresses.

6.3.1.3 Pressure Equalization

Between Modules

The Atmosphere Control and Supply Subsystem also provides

Manual Pressure Equalization Valves to equalize pressure between Space Station

modules while the hatch is closed.

A valve on each USOS hatch permits pressure equalization as modules are added to

the Station, during normal EVA activities, or in the event that a module has

been isolated in a contingency procedure.

There are similar pressure equalization devices on the ROS hatches.

6.3.1.4 Additional Atmosphere Control and Supply Capabilities at Assembly

Complete

At Assembly Complete, the Atmosphere Control and Supply

Subsystem will have the addition of an oxygen generator on the USOS and the

Sabatier on the ROS. The Sabatier

conserves Station resources by producing water through reaction of hydrogen from

the Elektron with carbon dioxide from the Atmosphere Revitalization Subsystem.

At Assembly Complete, Atmosphere Control and Supply will also provide

oxygen to the Water Recovery and Management Subsystem Potable Water Processor to

assist in the purification of Station water.

6.3.2 Atmosphere

Revitalization

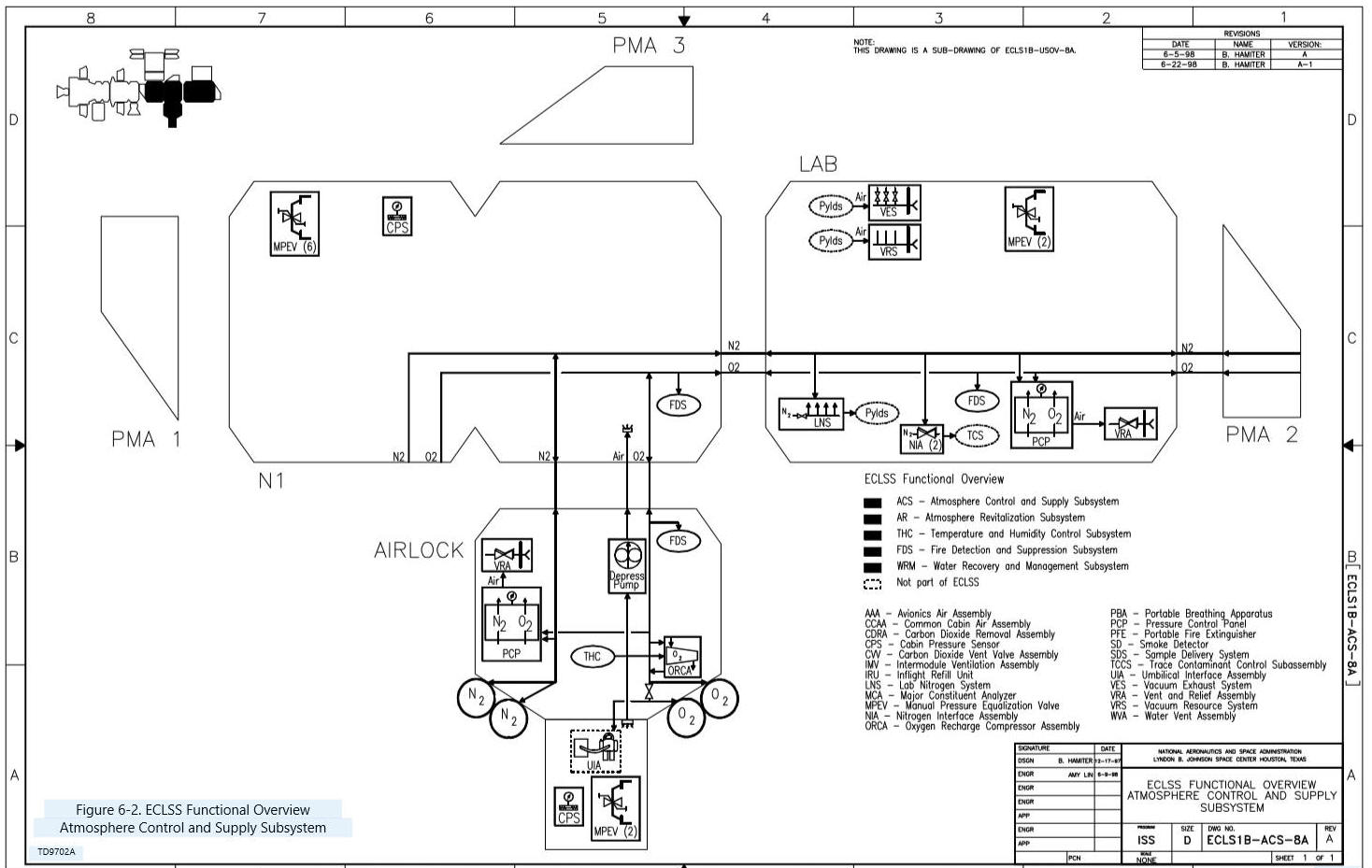

Figure 6-3

shows the USOS Atmosphere Revitalization Subsystem and its interfaces.

This subsystem ensures that the atmosphere provided by the Atmosphere

Control and Supply Subsystem remains safe and pleasant to breathe.

It performs carbon dioxide removal,

trace contaminant control, and major atmospheric constituent monitoring.

Figure 6-3 ECLSS Functional Overview USOS

Atmosphere Revitalization Subsystem and its Interfaces

6.3.2.1 Major Constituent

Monitoring

The Major Constituent Analyzer monitors the composition of

the Station atmosphere by mass spectrometry.

Measurements are used to control the addition of oxygen and indirectly,

nitrogen, into the Station atmosphere by the Atmosphere Control and Supply

Subsystem, and to monitor the performance of the assembly that removes carbon

dioxide. In the ROS, the Gas Analyzers use several different gas detection

methods to provide similar functions.

Air is delivered to the Major Constituent Analyzer by a network of pipes,

valves, and sample ports running throughout the USOS.

This network is the Sample Delivery System.

6.3.2.2 Carbon Dioxide

Removal

The Carbon Dioxide Removal Assembly (CDRA) collects carbon

dioxide from the cabin atmosphere with a series of regenerable sorbent beds and

expels the unwanted gases to space.

To remove carbon dioxide effectively, the CDRA requires cold, dry air, so it

receives air from the Temperature and Humidity Control Subsystem and interfaces

directly with the Internal Thermal Control System Low Temperature Loop.

On the ROS, the Vozdukh performs the same function as the CDRA.

Lithium hydroxide-based canisters are available for backup ROS

functionality.

6.3.2.3 Trace Contaminant

Control

The Trace Contaminant Control Subassembly filters and

catalyzes numerous gaseous contaminants and odors from the cabin atmosphere.

These contaminants are caused by material off-gassing, leaks, spills, or

other events. On the ROS, the Trace

Contaminant Control Unit operates similarly to the Trace Contaminant Control

Subassembly. The Harmful Impurities

Filter provides backup contaminant control as needed.

6.3.2.4 Additional Atmosphere

Revitalization Capabilities at Assembly Complete

At Assembly Complete, the USOS adds duplicates of each of

the Major Constituent Analyzer, Carbon Dioxide Removal Assembly (CDRA), and

Trace Contaminant Control Subassembly. These duplicates will serve as backup

only, because each device operates at a three-person rate. The ROS has similar

capabilities which will be used in conjunction with the USOS equipment, and

together they will be sufficient to support a six-member crew.

6.3.3 Temperature and

Humidity Control

Figure

6-4 shows the USOS Temperature and Humidity Control Subsystem and its

interfaces. This Subsystem helps maintain a habitable environment within the

Station atmosphere by circulating cool dry air, removing humidity and

particulates, and maintaining the temperature.

Circulation of the atmosphere minimizes temperature variations, ensures

homogeneous atmospheric composition, and provides a means for smoke detection.

Three levels of circulation are provided:

rack, intramodule, and intermodule ventilation.

Rack ventilation cools and circulates air within an individual rack.

Intramodule ventilation provides circulation to ensure a consistent

atmosphere within a single module, and may support cooling and humidity removal.

Finally, intermodule ventilation circulates air between modules to ensure

a homogeneous atmosphere throughout the Station.

While the ROS equivalent of Temperature and Humidity Control equipment is

considered a part of the ROS Thermal Control System, it is functionally very

similar to the USOS equipment.

Figure 6-4 ECLSS

Functional Overview Temperature and Humidity Control Subsystem

6.3.3.1 Rack Ventilation

The Avionics Air Assembly is used to cool and circulate air

within a specific rack volume. A

fan and non-condensing heat exchanger provide cooling for rack equipment and

circulation for operation of the Fire Detection and Suppression Subsystem Smoke

Detectors. This heat exchanger

interfaces with the Internal Thermal Control System Moderate Temperature Loop.

6.3.3.2 Intramodule

Ventilation

The Common Cabin Air Assembly (CCAA) contains a fan and

condensing heat exchanger to provide intramodule ventilation, temperature

control, and humidity removal.

Before the air enters the CCAA, it is drawn through the High Efficiency

Particulate Air (HEPA) filters which remove particles and bacteria from the

airstream. Moisture in the Station

atmosphere is condensed by the heat exchanger and is sent to the Water Recovery

and Management Subsystem. The heat exchanger interfaces with the Internal

Thermal Control System Low Temperature Loop. Air that has been cooled and

dehumidified is sent to the Atmosphere Revitalization Subsystem Carbon Dioxide

Removal Assembly (CDRA) for its effective operation.

There are two CCAAs in the U.S. Lab, of which only one is normally in

operation at Flight 8A. There is

also a CCAA in the Airlock which is only used during EVA operations.

The Cabin Air Fan in Node 1 provides intramodule circulation but has no

cooling or humidity removal capability.

6.3.3.3 Intermodule

Ventilation

The Intermodule Ventilation (IMV) Assembly is a series of

fans and valves that circulate air between modules through a ducting system.

Hard plumbed ducts are located in most endcones on the USOS, and the

hatches themselves can also act as circulation paths.

The ROS relies on drag-through flexible ducting and open hatches for

intermodule ventilation.

6.3.3.4

Additional Temperature and Humidity Control Capabilities at

Assembly Complete

At Assembly Complete, additional Common Cabin Air

Assemblies (CCAAs) will be available and Intermodule Ventilation (IMV) equipment

will be included in all new modules.

Additional Avionics Air Assemblies will be manifested as required to

support rack equipment.

6.3.4 Fire Detection and

Suppression

Figure

6-5 shows the USOS Fire Detection and Suppression Subsystem and its

interfaces. The Fire Detection and

Suppression Subsystem provides smoke detectors for the Station volumes, fire

extinguishers, portable breathing equipment, and a system of alarms and

automatic software responses for a fire event.

Following a fire, the Atmosphere Revitalization and Temperature and

Humidity Control Subsystems work together to remove contaminants from the

affected volume. In an extreme

situation, the Atmosphere Control and Supply equipment may be used to

depressurize a module to extinguish the fire and/or exhaust the contaminants.

Figure 6-5, ECLSS

Functional Overview Fire Detection and Suppression Subsystem

6.3.4.1 Smoke Detection

In the USOS, the Fire Detection and Suppression Subsystem

provides two area Smoke Detectors in each pressurized module, and a Smoke

Detector in each rack requiring an Avionics Air Assembly.

These Smoke Detectors operate on a light obscuration principle, and are

mounted in Temperature and Humidity Control Subsystem air paths.

The ROS has two types of Smoke Detectors.

One type is similar to USOS Smoke Detectors, and the other is an

ionization type.

A Caution and Warning (C&W) Panel mounted in each USOS

module features lighted emergency buttons.

If smoke is detected, flight software will light the “FIRE” button, sound

an alarm, and shut off Temperature and Humidity Control equipment in the area to

minimize oxygen being fed to the fire.

Crewmembers may also sound (or silence) a fire alarm by manually pushing

the button on the C&W Panel or on the Portable Computer System (PCS).

Fires on the USOS can be extinguished with handheld

Portable Fire Extinguishers, which are filled with carbon dioxide.

These function very similarly to typical fire extinguishers here on

Earth. Two different nozzles allow

the Portable Fire Extinguisher to be used on both open area and rack fires.

The ROS uses fire extinguishers filled with a non-toxic nitrogen based

substance that can be dispensed as a foam or a liquid.

6.3.4.4 Supplemental Oxygen

Supply

During a fire, crewmembers must wear a Portable Breathing

Apparatus (PBA), which is essentially a gas mask and an oxygen bottle.

The PBA can also be plugged into oxygen ports provided by the Atmosphere

Control and Supply Subsystem. The

PBA is particularly important for a crewmember using the Portable Fire

Extinguisher, because carbon dioxide displaces oxygen in the vicinity.

This high concentration of carbon dioxide could cause the crewmember to

lose consciousness if he or she is not supplied direct oxygen through a PBA.

6.3.4.5 Additional Fire

Detection and Suppression Capabilities at Assembly Complete

There are no functional differences between 8A and Assembly

Complete; there will simply be more equipment available.

6.3.5 Water Recovery and

Management

In Figure 6-6,

the USOS Water Recovery and Management Subsystem and its interfaces are

illustrated for a Flight 8A configuration.

This subsystem collects, stores, and distributes the Station's water

resources. The water collected

includes condensate from the Temperature and Humidity Control Subsystem and

return water from EVA activities.

At 8A, collected water is transported to the ROS for processing or is vented

overboard.

Figure 6-6, ECLSS Functional

Overview Water Recovery and Management Subsystem

6.3.5.1 ROS Water Recovery

and Management Overview

The ROS has primary responsibility for water recovery and

management functions for most of the assembly stages of the Station.

The ROS collects condensate water from its condensing heat exchangers and

receives water that is manually transported from the USOS.

It is then purified and monitored for quality.

If water is needed in the Elektron oxygen generator, potable water must

be repurified to remove minerals.

Small tanks are used to store and transport water in various locations on the

ROS. Larger tanks with a pump

assembly, called Rodniks, store potable water both on the exterior of the

Service Module and on Progress modules.

Solid waste products from various sources are collected and put on a

Progress module for incineration upon atmosphere re-entry.

6.3.5.2 USOS Water Recovery and Management

At Flight 8A, the USOS collects condensate water from the

Temperature and Humidity Control Subsystem and waste water from the

Extravehicular Mobility Units (space suits).

Waste water lines transport the water throughout the USOS, and the water

is stored in a tank until it is removed from the system by overboard venting or

manual transport to the ROS.

6.3.5.3 Additional Water

Recovery and Management Capabilities at Assembly Complete

At Assembly Complete, the USOS Water Recovery and

Management Subsystem has several more capabilities.

A network of pipes and another tank will be used to transport and store

water produced by the Shuttle’s fuel cells for use as make-up water on the ISS.

A Urine Processor will separate water from urine and refine it to waste

water. A Potable Water Processor

will then refine waste water (including condensate, fuel cell water, EVA waste

water, and Urine Processor output water) into potable water.

In Figure 6-7,

the interfaces that ECLSS shares with other ISS systems at Flight 8A are

illustrated. At Assembly Complete,

the USOS will also provide potable water to Crew Systems and to EVA Systems.

Figure

6-7. ECLSS interfaces at Flight 8A

There are several important milestones in the buildup of

ISS ECLSS. Because ECLSS is

primarily concerned with the maintenance of living conditions, these milestones

correspond to the arrival of pressurized modules.

6.5.1 Flight 1A/R -

Functional Cargo Block

The Functional Cargo Block (FGB) is the foundation module

of the ISS. It contains the first

few pieces of ECLSS equipment, including circulation fans and non-condensing

atmospheric heat exchangers, fire detection and suppression equipment, and a Gas

Analyzer.

At Flight 2A, Node 1 and two Pressurized Mating Adapters

(PMAs) are delivered to the Station. Node 1 contains a Cabin Air Fan,

Intermodule Ventilation equipment, a Cabin Pressure Sensor, Fire Detection and

Suppression equipment, and Manual Pressure Equalization Valves on each hatch.

6.5.3 Flight 1R - Service

Module

Most of the Russian ECLSS equipment on the Station at

Flight 8A is housed in the Service Module.

This includes the Elektron for oxygen generation, Vozdukh and lithium

hydroxidebased canisters for carbon dioxide removal, a Trace Contaminant Control

Unit and Harmful Impurities Filter for contaminant removal, Gas Analyzers for

major constituent monitoring, fire detection and suppression equipment, air

cooling and humidity removal equipment, urinal and commode facilities, and a

condensate water processor. The

arrival of the Service Module marks the beginning of the three-person permanent

presence capability.

Much of the USOS ECLSS equipment available during most of

the assembly stages arrives with the Lab.

Atmosphere Control and Supply equipment includes gas lines, Pressure

Control Assembly, and Manual Pressure Equalization Valves.

A complete rack of Atmosphere Revitalization equipment arrives, which

contains the Major Constituent Analyzer, Carbon Dioxide Removal Assembly, and

Trace Contaminant Control Subassembly.

The Sample Delivery System lines launched in the Lab and Node 1 are

connected to the Major Constituent Analyzer.

Temperature and Humidity Control equipment includes two Common Cabin Air

Assemblies and more Intermodule Ventilation equipment, as well as Avionics Air

Assemblies in several racks. Fire

Detection and Suppression equipment is launched with the Lab, as are the Water

Recovery and Management condensate tank, Water Vent Assembly, and waste and

(unused) fuel cell water lines.

At Flight 7A, the Airlock is installed, along with much of

the Atmosphere Control and Supply storage and distribution equipment, more

Manual Pressure Equalization Valves, and another Pressure Control Assembly.

Another Common Cabin Air Assembly and more Intermodule Ventilation

equipment arrive, and Sample Delivery System lines are connected to the USOS

network. The standard Fire

Detection and Suppression equipment is manifested, as is the Depressurization

Pump. This flight marks the last

major USOS ECLSS build-up until the arrival of Node 2.

6.6.1 ECLSS Purpose and

Functions

The Environmental Control and Life Support System (ECLSS)

maintains a pressurized habitable environment, provides water recovery and

storage, and provides fire detection and suppression within the ISS.

6.6.2 Subsystem Names and

Functions

There are five major subsystems within ECLSS:

· The Atmosphere Control and Supply Subsystem provides

oxygen and nitrogen to maintain the Station atmosphere at the correct pressure

and composition for human habitation. It also provides gas support to various

users on the Station, and pressure equalization and depressurization

capabilities

· The Atmosphere Revitalization Subsystem ensures that the

atmosphere provided by the Atmosphere Control and Supply Subsystem remains safe

and pleasant to breathe. It

performs carbon dioxide removal, trace contaminant control, and major

atmospheric constituent monitoring

· The Temperature and Humidity Control Subsystem helps

maintain a habitable environment by circulating air, removing humidity and

particulates, and maintaining the temperature of the Station atmosphere.

Three levels of circulation are provided:

rack, intramodule, and intermodule ventilation

· The Fire Detection and Suppression Subsystem provides

smoke detection sensors for the Station volumes, fire extinguishers, portable

breathing equipment, and a system of alarms and automatic software actions to

annunciate and automatically respond to a fire event

· The Water Recovery and Management Subsystem collects,

stores, and distributes the Station's water resources.

Figure 6-8 shows how all the

components of the subsystems interact with each other.

There are three major milestones in the buildup of USOS

ECLSS capabilities. On Flight 2A,

Node 1 contains the first pieces of USOS ECLSS equipment, consisting principally

of ventilation and Fire Detection and Suppression equipment.

Next, on Flight 5A, the Lab module carries a majority of the U.S. ECLSS

equipment discussed in this manual, including major portions of all subsystems.

Finally, on Flight 7A in the Airlock, the full capabilities of Atmosphere

Control and Supply are enabled, and additional Temperature and Humidity Control

and Fire Detection and Suppression equipment ensures crew health and comfort

during EVA operations.