APOLLO

11 OPERATIONS HANDBOOK BLOCK II SPACECRAFT

Spacesuit Assembly

(Intravehicular)

Bioinstrumentation

Harness and Biomed Belt

Shirtsleeve

Environment lntravehicular Apparel

Urine Collection

and Transfer Assembly and UCO Clamps

Communication

Soft Hat, Lightweight Headset, and Eartube

Constant Wear

Garment (CWG) "T" Adapter

Communications

Cable With Control Head

Pressure Garment

Assembly (PGA)

Intravehicular

Spacesuit Diagram

PGA and Helmet

Stowage Bags Diagram

Miscellaneous

Personal Equipment

Oxygen Hose

Assembly and Accessories Diagram

Extravehicular

Mobility Unit (EMU)

Crewman

Restraint Harness Subsystem With Heel Restraints

Restraint Harness

Buckle Stowage Straps

Diagram

Handholds, Hand

Straps and Hand Bar Diagram

Guidance and Navigation Station Restraint

Sleep Station

Restraints Diagram

Center Couch

Restraint Straps Diagram

Probe and Drogue

Stowage Straps Diagram

Velcro and Snaps

Retainer Locations

Sleep Restraint Tie

down Ropes

SIGHTING AND

ILLUMINATION AIDS

Internal Sighting

and Illumination Aids

Internal

Sighting and Illumination Aids Diagram

Window Shades and

Mirrors Diagram

Crewman Optical

Alignment Sight (COAS)

Crewman

Optical Alignment Sight System Diagram

LM Active Docking

Target Diagram

Center (Hatch)

Window Frame Markings

Right Rendezvous

Window Frame Markings

Miscellaneous

Internal Sighting and Illumination Aids Diagram

Miscellaneous

Internal Sighting and Illumination Aids Diagram

Meter Covers

(Altimeter and Accelerometer)

External Sighting

and Illumination Aids

External

Illumination Aids Diagram

EVA Handles With RL

Disks Diagram

Mission Operational

Aids Diagram

CREW PERSONAL

EQUIPMENT Diagram

Tools 3 and 4

Number 8 and 10 Torque Set Drivers

16 mm Data

Acquisition Camera Diagram

Data Acquisition

Camera Bracket

70 mm Hasselblad

Electric Camera and Accessories

70

mm Hasselblad Electric Camera and Accessories Diagram

Lunar Surface 70 mm

Film Magazine

70 mm Magazine LM

Transfer Bag

70 mm Camera Mount

for 80 and 250 mm Lens

70 mm Camera Mount

for 500 mm Lens

Accessories and

Miscellaneous Equipment

Accessory

and Miscellaneous Equipment Diagram Sheet 1

Accessories and

Miscellaneous Equipment Diagram 3

Accessory and

Miscellaneous Equipment Diagram Sheet 2

Voice Recorder,

Cassettes, and Battery Packs

Accessories and

Miscellaneous Equipment Decontamination Equipment Diagram

Vacuum Cleaning

Hose and Brushes

Utility

and Scientific Electrical Outlet Diagram

Scientific

Instrumentation Outlets

Drinking Water

Subsystem Diagram

Food Preparation

Water System Diagram

Waste Management

System and Supplies

Waste Management

System Diagram

Urine Subsystem

Components Diagram

Gemini Urine

Transfer System (UTS)

Urinating Using the

Urine Receptacle Assembly

Draining the UCTA

While in the Spacesuit

Draining the UCTA

After Removal From Spacesuit

Auxiliary Dump

Nozzle Operations Diagram

Waste Stowage Vent

System Diagram

Personal Hygiene

Items Diagram

Oral Hygiene Set -

Cleansing of Teeth

MEDICAL SUPPLIES

AND EQUIPMENT

Bioinstrumentation

Harness Diagram

Personal Biomedical

Sensors Instrument Assembly

Biomedical Signal

Conditioner Assembly

Bioinstrumentation

Accessories or Spares

Medical Accessories

Kit Diagram

RADIATION

MONITORING AND MEASURING EQUIPMENT

Radiation

Monitoring and Measuring Equipment Diagram

Personal Radiation

Dosimeter (PRD)

Van Allen Belt

Dosimeter (VABD)

Nuclear Particle

Detection System (NPDS)

Postlanding

Ventilation (PLV) Ducts

Postlanding

Ventilation Ducts Diagram

Swimmer Umbilical

and Dye Marker

Swimmer Umbilical

and Dye Marker Diagram

This section contains the description and operation of

Contractor and NASA- furnished crew personal equipment and miscellaneous

stowed equipment that is not described in other sections of the handbook.

All major items are identified as Contractor-furnished equipment (CFE) or

Government-furnished (NASA) property (GFP - synonymous with GFE).

The crew equipment will be presented in the general

order of operational usage. A brief outline is as follows:

A.

Spacesuits

1.

Intravehicular Spacesuit Assembly

(a)

Biomedical

Harness and Belt

(b)

Constant

Wear Garment (CWG)

(c)

Flight

Coveralls

(d)

Pressure

Garment Assembly (PGA)

(e)

Associated Umbilicals, Adapters , and Equipment

2.

Extravehicular Spacesuit Assembly

(a)

Liquid-Cooled

Garment (LCG)

(b)

PGA

with Integrated Thermal Meteroid Garment (ITMG)

2.

Interior

Handhold and Straps

3.

Hand Bar

C.

Zero-g

Restraints (paragraph 12 .1 2 .3)

2.

Velcro

and Snap Restraint Areas

3.

Straps

D.

Internal Sighting and Illumination Aids (paragraph 2.12.4)

2.

Mirrors

3.

Crewman Optical Alignment Sight (COAS)

E.

External Sighting and Illumination Aids

3.

Cameras

4.

Accessories & Miscellaneous

(a)

Waste

Bags

(b)

Pilot’s

Preference Kits (PPKs)

(d)

Oxygen

Masks

(e)

Utility

Outlets

(f)

Scientific Instrumentation Outlets

1.

Water

2.

Food

H.

Medical

Supplies and Equipment

I.

Radiation Monitoring and Measuring Equipment

1.

Postlanding Ventilation Ducts

2.

Swimmer

Umbilical and Dye Marker

6.

Survival

Kit

On the following pages is an alphabetical listing of

the stowable Apollo crew personal and miscellaneous equipment that will be

described in this section. Miscellaneous spacecraft equipment that is

mounted on spacecraft structure internally or externally is described in

this section but is not listed in the following chart.

|

Item |

CFE |

GFP |

Qty |

Dimensions |

Total Wt (Lb) |

Wt Each (Lb) |

Paragraph |

||

|

L |

W |

H |

|||||||

|

Adapter, CWG electrical, w bag |

|

X |

4 |

|

|

|

|

|

2.12.2 |

|

Adapter, contingency feeding |

|

X |

1 |

|

|

|

|

|

2.16.2 |

|

Adapter, gas sep drying |

|

X |

1 |

1.5” |

|

|

|

|

2.16.2 |

|

Adapter, urine hose to UCTA |

|

X |

1 |

5” |

1”D |

|

|

|

2.16.2 |

|

Bag accessory |

|

X |

3 |

|

|

|

.60 |

.20 |

2.12.5 |

|

Bag, helmet stowage |

|

X |

3 |

|

|

|

.99 |

.33 |

2.12.2 |

|

Bag, PGA stowage |

X |

|

1 |

32” |

18” |

2” |

|

4.3 |

2.12.2 |

|

Bag , gas separator |

X |

|

1 |

7” |

4” |

1.5” |

|

|

2.12.6 |

|

Bags, temp stowage |

X |

|

3 |

36” |

13” |

1” |

5.1 |

1.7 |

2.12.5 |

|

Bag, tunnel hatch |

X |

|

1 |

|

28”D |

|

|

|

2.12.3 |

|

Battery, voice recorder |

|

X |

5 |

2.0” |

1.8” |

0.65” |

|

|

2.12.5 |

|

Bracket, 16mm DAC |

X |

|

1 |

7” |

|

|

0.7 |

0.7 |

2.12.5 |

|

Brush, vac cleaning |

|

X |

2 |

1.63” |

1.8”D |

|

|

|

2.12.5 |

|

Cable, aux dump nozzle htr |

X |

|

1 |

108” |

|

|

|

0.2 |

2.12.6 |

|

Cable, grounding |

X |

|

1 |

|

|

|

|

|

2.12.5 |

|

Camera, 70 mm electric Hasselblad |

|

X |

1 |

5” |

4” |

5” |

|

4.04 |

2.12.5 |

|

Camera, 16 mm data acquisition with power cable |

|

X |

1 |

7” |

4” |

2” |

|

1.93 |

2.12.5 |

|

Cap, hose screen, w bag |

X |

|

3 |

|

|

|

1.00 |

0.20 |

2.12.2 |

|

Cap, gas sep nozzle |

|

X |

1 |

1” |

|

|

|

|

2.12.6 |

|

Cap, aux dump nozzle pressure |

X |

|

1 |

|

|

|

|

0.20 |

2.12.6 |

|

Cassette, 70 mn1 camera film |

|

X |

* |

|

|

|

|

|

|

|

Clamps, UCTA |

|

X |

3 |

|

|

|

0.03 |

0.01 |

2.12.2 |

|

Cloth, dry cleansing |

|

X |

* |

2” |

2” |

|

|

|

2.12.6 |

|

Cloth, wet cleansing |

|

X |

|

2” |

2” |

|

|

|

2.12.6 |

|

Communication cable |

X |

|

2 |

74” |

|

|

7.8 |

3.9 |

2.12.2 |

|

Communication cable w control head, w bag |

X |

|

2 |

121” |

|

|

8.4 |

4.2 |

2.12.2 |

|

Communication carrier (snoopy helmet) |

|

X |

3 |

|

|

|

|

|

2.12.2 |

|

Coupling, oxygen hose w bag |

X |

|

3 |

|

|

|

1.1 |

2.0 |

2.12.2 |

|

Container , decontamination, CU cam cassette |

X |

|

1 |

|

|

|

|

|

2.12.5 |

|

Container, decontamination, LSR |

X |

|

1 |

|

|

|

|

|

2.12.5 |

|

Container, decontamination, LSR (rock box),

large |

X |

|

1 |

|

|

|

|

|

2.12.5 |

|

Container, decontamination, 70 mm Hblad mag |

X |

|

1 |

|

|

|

|

|

2.12.5 |

|

Container, Frozen Food |

X |

|

1 |

|

|

|

|

|

2.12.6 |

|

Cover, meter |

|

X |

2 |

|

3”D |

|

|

|

2.12.4 |

|

Cover, PGA elec conn protective |

|

X |

3 |

|

|

|

|

|

2.12.3 |

|

Coveralls, inflight |

|

X |

3 |

|

|

|

9.7 |

3.2 |

2.12.2 |

|

Diaphragm, w cover |

X |

|

3 |

3” |

3”D |

|

|

|

2.12.6 |

|

Dishes |

X |

|

3 |

6” |

5” |

|

|

|

2.12.6 |

|

Docking target, LM active |

X |

|

1 |

8” |

8” |

|

|

1.8 |

2.12.4 |

|

Dosimeters, passive |

|

X |

9 |

|

|

|

0.18 |

0.02 |

2.12.8 |

|

Dosimeters, personal |

|

X |

3 |

|

|

|

1.14 |

0.38 |

2.12.8 |

|

Ducts, postlanding ventilation (PLV) w bag |

X |

|

3 |

|

|

|

0.60 |

0.10 |

2.12.9 |

|

Eartube, universal |

|

X |

3 |

|

|

|

0.03 |

0.01 |

2.12.2 |

|

Exerciser, inflight |

|

X |

1 |

|

|

|

|

1.22 |

2.12.5 |

|

Eyepatch |

|

X |

1 |

|

|

|

|

|

2.12.4 |

|

Fecal collection assy |

X |

|

30 |

8” |

3” |

1” |

4.20 |

0.14 |

2.12.4 |

|

Fecal containment system |

|

X |

3 |

|

|

|

1.50 |

0.50 |

2.12.2 |

|

Filter , red (Hblad cam) |

|

X |

1 |

|

|

|

|

0.05 |

2.12.5 |

|

Filter, high density, sun |

|

X |

2 |

|

|

|

2.8 |

1.4 |

2.12.4 |

|

Filter , Photar (HEC cam) |

|

X |

1 |

|

|

|

|

0.05 |

2.12.5 |

|

Filter , QD gas & liq |

X |

|

2 |

|

|

|

1.0 |

0.5 |

2.12.6 |

|

Fire extinguisher |

X |

|

1 |

8.5” |

5”D |

|

|

7.5 |

2.12.5 |

|

Flight data file with locker R12 |

X |

X |

* |

|

|

|

|

20.0 |

2.12.5 |

|

Food set |

|

X |

1 |

|

|

|

|

40.0 |

2.12.6 |

|

Food set, w hygiene items |

|

X |

1 |

|

|

|

|

30.8 |

2.12.6 |

|

Food warmer |

X |

|

1 |

10 |

6 |

7 |

|

|

2.12.6 |

|

Garment, constant wear (CWG) |

|

X |

6 |

Folded 12” |

6” |

2” |

5.6 |

0.8 |

2.12.2 |

|

Garment, liquid cooled |

|

X |

2 |

|

|

|

8.18 |

4.13 |

2.12.2 |

|

Glareshade, MDC |

X |

|

3 |

|

|

|

|

|

2.12.4 |

|

Glareshield, floodlight w bag |

|

X |

2 |

|

|

|

|

|

2.12.4 |

|

Gloves, IV (pr) |

|

X |

1 |

|

|

|

|

|

2.12.2 |

|

Handholds |

X |

|

2 |

|

|

|

|

|

2.12.3 |

|

Handbar |

X |

|

1 |

|

|

|

|

|

2.12.3 |

|

Hand straps |

X |

|

8 |

|

|

|

|

|

2.12.3 |

|

Harness, crewman restraint |

X |

|

3 |

|

|

|

|

|

2.12.3 |

|

Harness assy, bioinstrumentation |

|

X |

3 |

|

|

|

3.3 |

1.1 |

2.12.7 |

|

Headrest, pad |

|

X |

3 |

|

|

|

3.0 |

1.0 |

2.12.5 |

|

Headset, lightweight |

|

X |

3 |

|

|

|

0.9 |

0.3 |

2.12.2 |

|

Heel restraint, pr |

|

X |

3 |

4” |

3.5 |

1.0” |

3.3 |

1.0 |

2.12.5 |

|

Helmet, shield |

|

X |

1 |

|

|

|

|

0.79 |

2.12.2 |

|

Hook, line snagging w bag |

X |

|

1 |

|

|

|

1.7 |

1.9 |

2.12.9 |

|

Hose, vac cleaning |

X |

|

1 |

41.5” |

|

|

|

|

2.12.5 |

|

Hose assy, oxygen |

X |

|

2 |

72” |

|

|

10.6 |

5.3 |

2.12.2 |

|

Hot pad |

X |

|

1 |

9” |

4” |

|

|

|

2.12.6 |

|

Hygiene, oral assembly |

|

X |

1 |

|

|

|

1.0 |

0.3 |

2.12.6 |

|

Intervalometer |

|

X |

1 |

|

|

|

|

0.25 |

2.12.5 |

|

Kit, EMU maintenance |

|

X |

1 |

|

|

|

|

0.38 |

2.12.2 |

|

Kit, medical |

|

X |

1 |

7” |

5” |

5” |

|

3.0 |

2.12.7 |

|

Kit, pilot's preference |

|

X |

3 |

|

|

|

1.5 |

0.5 |

2.12.5 |

|

Lens , 5 mm ( 16 mm camera (with cover) |

|

X |

1 |

|

|

|

|

0.68 |

2.12.5 |

|

Lens , 18 mm ( 16 mm camera) |

|

X |

1 |

|

|

|

|

0.56 |

2.12.5 |

|

Lens , 18 mm Kern (16 mm cam |

|

X |

1 |

|

|

|

|

0.48 |

2.12.5 |

|

Lens, 75 mm (16 mm camera) |

|

X |

1 |

|

|

|

|

0.53 |

2.12.5 |

|

Lens, 75 mm Kern (16 mm cam) |

|

X |

1 |

|

|

|

|

0.50 |

2.12.5 |

|

Lens, 250 mm (70 mm Hasselblad) |

|

X |

1 |

6.2” |

3.1” |

3.1” |

|

2.10 |

2.12.5 |

|

Lens, 500 mm (70 mm (Hblad) |

|

X |

1 |

12.5” |

3.5” |

|

|

|

2.12.5 |

|

Life vest |

|

X |

3 |

|

|

|

7.5 |

2.5 |

2.12.2 |

|

Magazines, 70 mm camera film |

|

X |

* |

3.82” |

3.6” |

1.86” |

|

0.76 |

2.12.5 |

|

Magazines, lunar surface Hasselblad |

|

X |

1 |

|

|

|

|

1.75 |

2.12.5 |

|

Magazines, 16 mm OAC |

|

X |

* |

|

|

|

|

0.97 |

2.12.5 |

|

Masks, oxygen whose |

|

X |

3 |

|

|

|

3.60 |

1.30 |

2.12.5 |

|

Meter, radiation survey |

|

X |

1 |

|

|

|

|

1.60 |

2.12.8 |

|

Mirror assy, internal

viewing |

X |

|

3 |

4.25 |

3.5 |

|

|

|

2.12.4 |

|

Mirror, 16 mm camera right angle |

|

X |

1 |

|

|

|

|

0.16 |

2.12.5 |

|

Monocular |

|

X |

1 |

|

|

|

|

0.75 |

2.12.4 |

|

Mount, 70 mm Hblad |

|

X |

1 |

9” |

|

|

|

|

2.12.5 |

|

Pencil |

|

X |

3 |

|

|

|

0.15 |

0.05 |

2.12.2 |

|

Penlights |

|

X |

6 |

7” |

1.5” |

|

2.04 |

0.34 |

2.12.2 |

|

Pen, marker |

|

X |

3 |

|

|

|

0.15 |

0.05 |

2.12.2 |

|

Pens, data recording |

|

X |

3 |

|

|

|

0.15 |

0.05 |

2.12.2 |

|

Pouch, food retainer |

|

X |

2 |

|

|

|

|

|

2.12.6 |

|

Pump, sea water |

X |

|

1 |

|

|

|

|

1.60 |

2.12.9 |

|

QD, aux dump nozzle |

X |

|

1 |

4” |

1”D |

|

|

0.20 |

2.12.6 |

|

QD, water (waste) panel |

X |

|

1 |

4.5” |

1”D |

|

|

0.30 |

2.12.6 |

|

Restraint, sleep station |

X |

|

3 |

|

|

|

10.8 |

3.60 |

2.12.3 |

|

Ring sight |

|

X |

1 |

1.26” |

1.2” |

0.64” |

0.08 |

|

2.12.5 |

|

Rollon cuff assembly |

|

X |

3 |

|

|

|

|

|

2.12.6 |

|

Ropes, sleep restraint tiedown |

X |

|

5 |

10’ |

0.3”D |

|

3.5 |

0.7 |

2.12.3 |

|

Scissors (large) |

|

X |

3 |

8” |

2” |

|

1.62 |

0.53 |

2.12.2 |

|

Separator, gas |

|

X |

2 |

6” |

|

|

|

|

2.12.6 |

|

Shades, rendezvous window |

X |

|

2 |

13” |

8” |

|

0.24 |

0.12 |

2.12.4 |

|

Shade, side hatch |

X |

|

1 |

|

10”D |

|

|

1.4 |

2.12.4 |

|

Shades, side viewing window |

X |

|

2 |

13” |

13” |

|

3.4 |

1.7 |

2.12.4 |

|

Sight, crew optical alignment (COAS) w filter |

X |

|

1 |

8” |

2”D |

|

|

1.5 |

2.12.4 |

|

Spacesuit, intravehicular |

|

X |

1 |

|

|

|

|

35.61 |

2.12.2 |

|

Spacesuit, extravehicular |

|

X |

2 |

|

|

|

94.72 |

47.36 |

2.12.2 |

|

Spotmeter, automatic |

|

X |

1 |

7” |

4” |

|

|

.94 |

2.12.5 |

|

Straps, utility |

X |

|

13 |

12” |

|

|

0.39 |

0.03 |

2.12.3 |

|

Strap, center couch DPS burn |

X |

|

1 |

|

|

|

|

0.2 |

2.12.3 |

|

Straps, center couch stow |

X |

|

2 |

|

|

|

|

|

2.12.3 |

|

Straps, control cable |

X |

|

4 |

11” |

|

|

|

|

2.12.3 |

|

Straps, drogue stow |

X |

|

3 |

|

|

|

|

|

2.12.3 |

|

Straps, glareshade |

X |

|

4 |

5.5” |

|

|

|

|

2.12.3 |

|

Straps, probe stowage |

X |

|

2 |

|

|

|

|

|

2.12.3 |

|

Straps, cable routing |

X |

|

3 |

5.5” |

|

|

|

|

2.12.3 |

|

Sunglasses with pouch |

|

X |

3 |

|

|

|

0.06 |

0.02 |

2.12.2 |

|

Survival rucksack 1 |

|

X |

1 |

18.0” |

6.0” |

6.0” |

|

34.9 |

2.12.9 |

|

Survival rucksack 2 |

|

X |

1 |

18.0” |

6.0” |

6.0” |

|

34.9 |

2.12.9 |

|

Tape cassette, voice recorder |

|

X |

5 |

3.9” |

25” |

0.4” |

0.5 |

0.1 |

2.12.5 |

|

Tape ( roll) |

|

X |

1 |

6”D |

|

|

|

.88 |

2.12.5 |

|

Timer, two speed |

|

X |

1 |

|

|

|

0.4 |

0.4 |

2.12.5 |

|

Tissue dispensers |

|

X |

7 |

8” |

4” |

3” |

0.39 |

1.42 |

2.12.6 |

|

Toolset, inflight |

X |

|

1 |

|

|

|

|

4.6 |

2.12.5 |

|

Towels, utility (pack) |

|

X |

3 |

|

|

|

2.49 |

0.83 |

2.12.6 |

|

Urine collection & transfer assembly |

|

X |

3 |

|

|

|

1.29 |

0.43 |

2.12.2 |

|

Urine hose |

|

X |

1 |

120” |

1”D |

|

1.30 |

1.30 |

2.12.6 |

|

Urine transfer system (Gemini) |

|

X |

3 |

12” |

9” |

1” |

|

1.3 |

2.12.6 |

|

Uri ne receptacle assy |

X |

|

1 |

|

|

|

|

|

2.12.6 |

|

Vacuum brush |

|

X |

2 |

|

|

1.63” |

|

|

2.12.5 |

|

Vacuum hose |

X |

|

1 |

39” |

|

|

|

|

2.12.5 |

|

Vacuum QD (cabin vent) |

X |

|

1 |

5” |

1.5”D |

|

|

|

2.12.6 |

|

Voice recorder |

|

X |

1 |

5.3” |

|

|

1.2 |

1.2 |

2.12.5 |

|

Watch with watchband |

|

X |

3 |

|

|

|

0.45 |

0.15 |

2.12.2 |

|

Water metering dispenser |

|

X |

1 |

9” |

|

|

|

1.5 |

2.12.6 |

A spacesuit is an enclosed unit that provides a crewman

with a life supporting atmosphere and protective apparel in a space

environment. It will be considered in two conditions: intra vehicular and

extravehicular.

In the intravehicular condition, the apparel is called

the intravehicular spacesuit and consists of the bioinstrumentation

harness assembly, a constant wear garment (CWG), a pressure garment

assembly (PGA) with intravehicular cover (IC), and associated equipment

(contained on or within the spacesuit). The adapters and umbilical hoses

that connect the space suit to the spacecraft systems are also described

in this subsection.

In the extravehicular condition, the apparel is called

the extravehicular mobility unit (EMU) and consists of a fecal containment

system, a urine collection and transfer assembly (UCTA), the

bioinstrumentation harness assembly, a liquid-cooled garment (LCG),

communications soft hat, an extravehicular spacesuit, a portable life

support system (PLSS), oxygen purge system (OPS), integrated thermal

micrometeoroid garment (ITMG), an extravehicular visor assembly (EV

visor), and associated equipment contained on or within the E MU. The PLSS

and OPS will not be described in this handbook.

Spacesuit Assembly (Intravehicular)

The intra vehicular spacesuit is depicted in Spacesuits Diagram. The

intravehicular condition has two subconditions, unsuited and suited. In

the unsuited condition or "shirtsleeve environment, " the crewman breathes

the oxygen in the spacecraft cabin and wears a bioinstrumentation harness,

a communication soft hat for communication, a constant wear garment (CWG)

for comfort, flight coveralls for warmth, and booties for zero-g

restraint. A CWG adapter is used to connect the communications soft hat

(CSH) and the bioinstrumentation harness signals to the communications

cable. The comm cable attaches to connectors between panel s 300 and 301

to complete the signal flow to the audio center.

In the suited condition, the crewman wears his

bioinstrumentation harness, a communication soft hat, a CWG, a pressure

garment assembly (PGA) with IC, and breathes oxygen within the garment. An

oxygen hose assembly delivers the oxygen to the suit and returns it to the

ECS. The comm cable connects directly to the PGA for telecommunications

signal flow. In this condition there are two ECS modes of operation,

ventilated and pressurized.

Bioinstrumentation

Harness and Biomed Belt

(Shirtsleeve

Environment lntravehicular Apparel).

Shirtsleeve

Environment lntravehicular Apparel

The purpose of the bioinstrumentation harness is to

furnish the biomedical signals to monitor the crews’ physical condition,

and consists of sensors, signal conditioners, a biomed belt, and wire

signal carriers. For a complete description, refer to

Medical Supplies and Equipment.

Each crewman will have sensors attached to his skin for

the entire mission. These sensors have wire leads encased in plastic with

a small connector at the other end. The connectors are inserted through

the CWG and connected to the signal conditioners in the biomed belt. The

biomed belt is cloth, has four pockets, and snaps in the corners to attach

to the CWG.

There are three signal conditioners: one for ECG, one

for the impedance pneumograph (ZP), and one dc-dc converter which fits

into pockets on the biomed belt, located around the abdomen. The signal

conditioners are interconnected by a wire harness which has a 9-socket

connector.

The fecal containment system (FCS) is a chemically

treated under pant worn under the LCG during periods of extravehicular

activity (EVA). In the event of an uncontrolled bowel movement, the

chemicals in the underpant will neutralize the feces. At launch and entry,

the fecal containment systems are stowed. Spacesuits Diagram

Urine Collection and Transfer Assembly and UCO Clamps

The urine collection and transfer assembly (UCTA)

functions to transfer the urine from the suited crewman to the suit during

emergency urinations

Spacesuits Diagram. This condition could occur during a "hold"

on the launch pad or EVA.

The UCTA consists of a belt, shaped bladder, roll-on

(external catheter), and a tube leading to the spacesuit urine collection

QD.

The UCTA is donned over the fecal containment system.

When doffing the UCTA, the_ UCD clamps are used to seal urine in the tube

to prevent leakage into the crew compartment. The urine in the UCTA can be

drained while it is in the spacesuit or after it is removed. For the

procedure, refer to section

2.12.6.

Constant Wear Garment (CWG) (Shirtsleeve Environment lntravehicular Apparel)

The constant wear garment (CWG) is used as an

undergarment for the PGA and provides warmth for the crewman while

unsuited in the shirtsleeve environment. As an additional purpose, this

garment provides an attach point for the biomed belt.

The CWG is a porous cloth, one-piece garment similar to

long underwear. It has a zipper from the waist to the neck for donning and

doffing. An opening in front is for urination and one in the rear for

defecation, without CWG removal. There are snaps at the mid-section to I

attach the biomed belt with signal conditioners, and pockets for film

packet passive dosimeters at the ankles, thighs, and chest. It also has

integral socks.

The CWG can be worn for 6 to 7 days before a change is

required. Three CWGs will be worn aboard by the crew with three being

stowed in a locker, allowing one CWG change each.

Flight Coveralls (Shirtsleeve Environment lntravehicular Apparel)

The flight coveralls help keep the CWG clean, provide

additional crewman warmth,· and provide stowage for miscellaneous personal

equipment while in a shirtsleeve environment. It is a two-piece garment

and 1s stowed at launch and entry. Accessories include a pair of booties

with Velcro patches on the soles for restraint.

Communication Soft Hat, Lightweight Headset, and Eartube (Shirtsleeve Environment lntravehicular Apparel)

The communication soft hat is worn at all times, in or

out of the PGA, for the purpose of communications. Alternate names for it

is communications carrier (comm carrier) or "Snoopy" helmet.

The comm soft hat has two earphones and two

microphones, with voice tubes on two mounts that fit over the ears. The

hat or helmet is cloth and has lacing to adjust the fit to the individual

crewman. A chin strap secures the hat to the head. A small pocket on the

inside near the right temple will hold a passive dosimeter film packet. An

electrical cable with a 21-socket connector will connect to the CWG

adapter or PGA.

The lightweight headset is a single microphone and

earpiece held on the head by a head band. It can be used in place of the

comm carrier while in a shirtsleeve environment.

The universal ear tube attaches to the lightweight

headset earphone. The ear tube is a short length of plastic tube with an

ear fitting that conducts sound from the earphone to the ear. It is stowed

in a pocket of the in-flight coverall.

Constant Wear Garment (CWG) "T" Adapter (Shirtsleeve Environment lntravehicular Apparel)

Communications and bioinstrumentation signals are

transmitted to the communications cable by the CWG T-Adapter; it is used

when in the shirtsleeve environment.

The CWG T-Adapter has a 6 1-socket connector pull in

the middle, and two pigtails, one with a 9-pin connector and one with a

21-pin connector.

There are three CWG “T” Adapters which are stowed when

not in use plus a spare.

Communications Cable With Control Head

The communications cable, or comm cable, transmits

voice communications and bioinstrumentation signals from the adapters and

crew to the spacecraft bulkhead connectors. It also carries electrical

power and the caution warning (C/W) system audible alarm signal.

The comm cable consists of a control head and a cable.

The control head has a 61-pin connector, a rocker switch and a 37-pin

connector. The cable has a 37-pin connector at one end and a 37-pin

connector with a lanyard pull at the spacecraft bulkhead end. The cables

for the Commander and CM Pilot are 74 inches long. The LM Pilot's cable is

121 inches in length, which allows it to be used for crew transfer through

the tunnel into the LM. One spare control head and cable (121 inches) is

carried in the event of a malfunction.

Pressure Garment Assembly (PGA) (Intravehicular Spacesuit Diagram)

Intravehicular

Spacesuit Diagram

The major component of the spacesuit is the pressure

garment assembly (PGA). The A 7L pressure garment assembly (PGA) provides

a mobile life support chamber that can be pressurized separately from the

cabin inner structure in case of a leak or puncture. The PGA consists of a

helmet, gloves, and torso and limb assembly. It requires an oxygen hose

for oxygen and electrical cable for telecommunications.

The blue torso has a neck ring for securing the helmet

and wrist rings for securing the gloves. It is constructed of Beta cloth

(a fiberglasstype material). A double zipper runs from the crotch area

along the back to the neck ring for donning and doffing. Snaps are located

on the upper chest for securing the life vest. The right wrist area has a

pressure gage with a range of 2 to 5 psia. Two cables run laterally from

the chest, around the biceps, to the spine as an anti-ballooning device,

and are attached and detached at the chest. Two adjustment straps

restraining the neck ring are located in the front (sternal area) and rear

(spinal area).

On the right chest area is a 61 -pin telecommunications

connector. When not in use and during stowage, the connector is protected

by a PGA electrical connector protective cover. The inside

telecommunications harness splits to a 9-pin connector

(bioinstrumentation) and a 21-pin connector (communications). On the left

chest area is a connector for the FLSS liquid system. Inside, it has a

supply hose and a return hose with connectors that connect to the liquid

cooled garment (LCG) when worn in place of the CWG.

Two sets of oxygen hose connectors are located· on the

left- and right-lower rib cage area. A set consists of a blue supply

connector and red return connector. The left connector set is normally for

the PLSS hoses and the right set for the CM ECS hoses, ·but the oxygen

hose connectors will fit either set. To prevent an alien object from

entering and damaging a spacesuit Oz hose connector, a PGA gas connector

plug (Intravehicular

Spacesuit Diagram) is inserted when an O2

connector is not in use. The gas connector plugs are color coded red and

blue to match the O2

connectors. To insert, fit the plug into the connector and press until it

clicks. It mechanically locks in place. To remove, unlock the plug by

pressing the gold lockpin, then lift the locking tabs, rotate the locking

ring, and pull the plug. The intravehicular PGA or spacesuit has only one

set of hose connectors on the right side as there is no extravehicular or

FLSS requirement.

Leg pockets are placed in accordance with the defined

locations. These are used to contain the numerous personal items.

Additional pockets are strapped on the legs to hold other miscellaneous

items. The boots are integral to the torso and the soles have Velcro

patches for restraint. The boot heels have partial steel plates to wedge

in the couch footpan cleats for restraining the feet. The gloves secure to

the wrist ring with a slide lock and rotate by means of a ball bearing

race.

The intravehicular cover (IC) is for added wear

protection of the torso. It is also Beta cloth, with external teflon

patches at maximum wear points. The cover will be laced over the torso and

limbs for operational use and intravehicular (IV) gloves will be worn to

protect the PGA gloves when performing rough handling tasks. The PGA with

the intra vehicular cover is commonly called an intravehicular spacesuit.

The PGA with the integrated thermal micrometeoroid garment (ITMG) is

termed the extravehicular spacesuit. For mission or operational purposes,

the spacesuit includes the PGA and the IC or ITMG.

The helmet is a plastic bubble. It secures to the torso

neck ring with a slide lock. A slot channel at the rear of the neck ring

receives oxygen from the torso ventilation duct and directs it to a

one-half-inch-thick foam plastic manifold. The manifold lays on the aft

quarter of helmet, terminating at the top. Numerous slits in the manifold

direct the oxygen across the face, purging the helmet of carbon dioxide.

On the left side, near the mouth, is a feed port and a feed port cover. A

contingency feeding valve adapter is provided with the food set and will

attach to the feed port to provide a method of emergency nourishment. Only

drinks will pass through. The helmet shield (HS) (Intravehicular Spacesuit Diagram)

is a plastic cover to be used during intra vehicular activities (remove

/replace probe or tunnel hatch) to prevent damage to the PGA helmet. Only

one shield is provided per spacecraft.

Additional subassemblies or accessories are donning

lanyards for doffing/donning, a neck dam for restricting water during post

recovery CM egress, and strap-on leg pockets for scissors, checklists, and

data lists.

After attaining earth orbit, the PGA is stowed in two

parts: torso (with gloves) and the helmet. The torso (with gloves) fits

into an L-shaped, expandable bag (3 PGA capacity), and is attached to the

aft bulkhead and the center c ouch by hooks. (See the

PGA and Helmet Stowage Bags

Diagram). The helmet shield and inflight coveralls are also

stowed in the PGA stowage bag.

PGA and Helmet

Stowage Bags Diagram

The PGA helmet stowage bag is made of Beta cloth. The

"dome" end 1s closed, and the open end has a draw string for closure. Four

straps with snaps and Velcro are attached for restraints (Personal Equipment Diagram).

At launch the helmet bags are collapsed and stowed. When the helmet is

doffed it is placed in a helmet bag, the draw strings are tied and

attached to the right and left-hand equipment bays by the snaps on the

straps. For entry, the helmet bags are again collapsed and stowed after

the helmet is donned or left on the stowed helmet in the event of an

unsuited entry.

In the event the command module inner structure loses

pressure, the ECS can maintain a pressure of 3.5 psia for 15 minutes to

allow the crewmen to don their PGAs.

To don the PGA, clear the legs and arms of

obstructions, and verify the zippers are run to the neck ring with

lanyards attached and oxygen hoses are connected. Place the legs in the

boots and legs of the torso and connect the bioinstrumentation and

communication harness. Place arms in torso arms and the head through neck

ring. Pull the lanyard connected to the inner zipper and outer zipper to

crotch, closing the stress relieving and pressure seals. Connect and lock

shoulder cables.

Don the helmet by connecting it to ·torso neck ring and

rotate the neck ring lock. Complete the donning by putting the gloves on

and locking. Adjust the ECS suit flow regulator.

To doff the PGA, remove the gloves and helmet, unzip

from the crotch to the neck ring, and withdraw neck and arms. Disconnect

the bioinstrumentation and communication harness, and remove legs from the

torso.

In the suited condition, there are two modes: the

normal or "ventilated" and "pressurized." In both cases, the helmet is on

and locked.

In the ventilated mode sometimes referred to as

"vented," the cabin is pressurized at 5 psi and the suit is 5.072 psi, or

a positive pressure differential of 2 inches of water in the suit. This

state allows comfort and maximum mobility for the crewman. The flow rate

through the suit will be approximately 7 to 11 cubic feet per minute.

The oxygen is delivered by the oxygen supply hose,

routed to the helmet and midsection to be purged to the extremities, and

returned via ventilation tubes to the midsection return connector and

oxygen hose.

In the event the cabin pressure decreases to 3.5 psia

or lower, the ECS will maintain 3.7 psia in the PGA. This mode is

"pressurized,” and the flow rate will be more than 12.33 pounds per hour

and less than 17 pounds per hour. The crewmen will have to overcome the

pressurized balloon effect and mobility will be more restricted than the

vented mode.

Miscellaneous

Personal Equipment

Personal items of equipment that are used many times

and must be immediately accessible are stowed in spacesuits, pockets or

attachable pockets. These items must also be transferred to the flight

coveralls after doffing the spacesuit. The following is the nomenclature

and description of these items. (See

Personal Equipment Diagram)

•

Penlight - Small, two-cell unit

used for portable lighting

•

Sunglasses with pouch

•

Personal Radiation Dosimeter - A

cigarette package shaped unit, battery powered dosimeter which indicates

accumulated dosage (rads) by its register readout

•

Chronograph With Watchband -

11Accutron Astronaut" watch featuring sweep second hand, stopwatch

control, and changeable time zone dial

•

Marker Pen - Felt-tip pen used

for marking sanitation bag assemblies, refuse bags, and Log Book

•

Pencil

•

Data Recording Pens - Pressurized

ball point pens for writing

•

Scissors - Surgical scissors,

used for cutting food bags, pouches, etc.

•

Life Vest - Attacl1ed to PGA

during boost and entry; stows on the PGA stowage bag during the remainder

of the mission

•

Slide Rule - Standard slide rule,

6 inches long, aluminum.

•

Motion Sickness Bag - A plastic

emesis bag in a small wrapper.

Oxygen Hose Assembly (Oxygen Hose Assembly and Accessories Diagram)

Oxygen

Hose Assembly and Accessories Diagram

The oxygen hoses are flexible silicon rubber hoses with

a convoluted wire reinforcement and 1. 25-inch inside diameter. Each

assembly has two hoses, a double "D" section and connector at the ECS end,

and two separate connectors at the suit end (supply and/ or return). The

assembly is covered with beta cloth and the hoses are fastened together

with keepers every 12 inches. Also, at 12-inch intervals along the hose,

cloth straps with fasteners for securing the comm cable are provided. When

coupled together as a unit, the hose and cable is referred to as an

umbilical assembly.

The hoses for the left and center crewman are 72 inches

long and the right crewman’s hose is 119 inches in length.

When the oxygen hose is not connected to the PGA, the

ECS end will remain attached to the valve at the left-hand forward

equipment bay and the oxygen hose will be stowed. Straps on the CM

structure will aid in routing the hoses across the forward bulkhead and

right-hand forward equipment bay.

Oxygen Hose Coupling (Oxygen Hose Assembly and Accessories Diagram)

To prevent fresh oxygen from returning through the

exhaust or return end of the O2

hose while the suit circuit return valve is open, a coupling is placed

over the return end. It is a 5-inch aluminum tube with a web seal in the

middle and hose connectors at each end. During an EVA, both nozzles

(supply and return) are plugged into the coupling connectors, thus sealing

both nozzles.

Oxygen Hose Screen Caps (Oxygen Hose Assembly and Accessories Diagram)

In the shirtsleeve environment, the crew compartment

oxygen returns to the ECS suit loop through the suit circuit return valve

which has a screen cover functioning as a preliminary debris trap. The

screen has to be cleaned periodically but the task is difficult because of

obstructions. By placing the screen caps on the oxygen return nozzles

(red), placing the flow control valves on panels 300, 301, and 302 in the

CABIN FLOW position, the return oxygen is split between the oxygen hoses

and the suit circuit return valve. The oxygen is screened for debris at

the cap screens, which is accessible and easy to clean but also greatly

reduces the flow. Therefore, the oxygen hose screen caps are used to delay

the cleaning of the suit circuit return valve. A screen cap on an oxygen

return hose nozzle (red) can also be used for vacuuming debris in the crew

compartment.

The screen cap is a fluorel tube with a monel screen

(#30 mesh) at one end and an internal ridge at the other. It slides over

the return nozzle and engages a groove to retain it. There are three

screen caps per spacecraft.

When the screen cap becomes clogged with debris, it can

be cleaned by using a small piece of utility tape to blot the screen. The

tape can be inserted in a utility bag, food bag, or waste bag for

disposal.

In the event the spacesuit PGA is damaged, it can be

repaired by use of the EMU maintenance kit. The kit is approximately 8 x 6

x 1. 5 inches and weighs 0.38 pound. There is one kit aboard the CM,

stowed in a locker on the aft bulkhead.

Extravehicular Spacesuit (Spacesuits Diagram)

The extravehicular spacesuit is identical to the intra

vehicular space suit with the exception of the oxygen connectors, the

cover, and the substitution of the LCG for the CWG. There are two sets of

oxygen connectors, on the left chest and on the right chest of the

extravehicular space suit PGA. These are necessary because the commander

(CDR) and lunar module pilot (LMP) transfer to the LM ECS while CM oxygen

hoses are attached to their spacesuit.

The cover, or integrated thermal micrometeoroid cover

(ITMG), is similar to the IC but is thicker and heavier. It consists of an

outer protective layer with scuff patches at the knees and elbows, seven

alternating layers of beta cloth felt (micrometeoroid protection) and

silverized mylar (thermal protection), and a liner . The ITMG is also

laced on the PGA for the mission.

Liquid Cooled Garment (LCG) (Spacesuits Diagram)

The LCG is worn in place of the CWG when the CDR and

LMP transfers to the LM or performs E VA. The LCG contains small plastic

tubes (0.125-inch diameter) sewn to a netting that covers the crewman's

body through which water circulates, absorbing body heat. The water is

transported to the FLSS where the sublimator expels the heat. The LCG has

a thin cloth lining that prevents the hands and feet from entangling the

plastic tubes when donning.

Two LCGs are vacuum packed and stowed in a locker on

the aft bulkhead. They are fully charged with water and, when donning,

must be connected to the EV spacesuit multiple water connector. When the

CDR and LMP return to the CSM after LM or extravehicular activities, the

LCG must be disconnected, doffed, folded, and stowed in a locker.

Extravehicular Mobility Unit (EMU)

For clarity, the EMU will be briefly described. Most of

the components, other than the EV spacesuit, are stowed aboard the LM. As

stated in the SPACESUITS section,

the EMU consists of a FCS, UCTA, bioinstrumentation harness assembly, LCG,

EV spacesuit, a FLSS, OPS, EVVA, EV gloves, and a pair of lunar overshoes

(LO).

The portable life support system (FLSS) is a "backpack"

unit that I furnishes oxygen for breathing, cooled water for the LCG, and

communications while the crew is on the lunar surface or performing EVA.

It has a 4-hour oxygen supply and can be recharged from the LM. One of its

LiOH canisters will be returned in the CM for analyzing. The PLSS water

subsystem is part of the heat exchanging system. The heat is lost by

sublimation. The communications system allows the lunar explorer to

communicate to the LM or CSM which will relay to earth.

Two PLSSs are stowed in the LM a t launch. They will be

donned and checked out prior to EVA. One or both PLSSs will be left on the

lunar surface to lighten the LM ascent vehicle or left in the LM.

The oxygen purge system (OPS) is a small oxygen unit

that furnishes emergency oxygen to the crewman during EVA. It is about the

size of a 2-pound loaf of bread and has a 30-minute oxygen supply. It

attaches to the top of the PLSS or in the stomach area by straps. Oxygen

is delivered through a hose into the PGA oxygen connector, purges the

helmet with oxygen, and exits through the suit outlet connector and purge

valve.

Two OPSs are stowed aboard the LM at launch and both

will be returned to the LM from lunar exploration. If not needed for

extravehicular transfer, they will be l eft on the LM. If used for EVA

transfer, the OPS will be jettisoned.

The extravehicular visor assembly (EVVA) is a

double-shelled visor that fits over the PGA helmet and is used for EVA.

The outer shell is vacuum deposited gold plated. The EVVA is stowed aboard

the LM at launch and left aboard the LM in lunar orbit or jettisoned.

The EV gloves and lunar overshoes (LO) are used for EVA

and lunar exploration. They are aboard the LM at launch and are left

aboard the LM in lunar orbit or jettisoned.

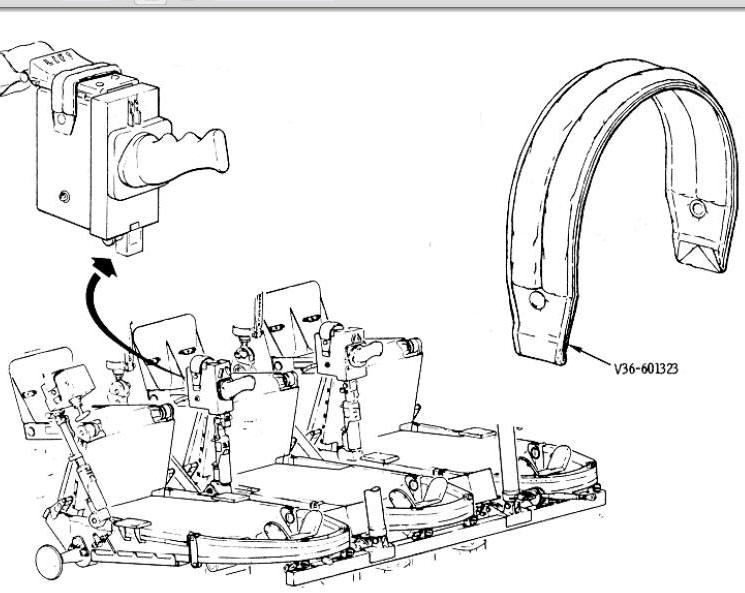

Crewman Restrain Harness (Crewman Restraint Harness Subsystem With Heel Restraints)

There are three restraint harnesses per spacecraft, one

for each crewman. The harnesses are attached to the crew couches. The

restraint harness consists of a lap belt and two shoulder straps

interfacing the lap belt at the buckle. The lap belt straps are connected

to the seat pan and back pan. This configuration provides adequate hip

support. The shoulder straps are connected to shoulder beam of the couch.

Crewman

Restraint Harness Subsystem With Heel Restraints

The lap belt buckle is a lever-operated, three-point

release mechanism. By pulling a lever, the shoulder straps and right- lap

belt strap will be released. The strap ends are equipped with snaps which

may be fastened to mating snaps on the couch and struts when not in use.

The restraint harness buckle can be restrained when not in use by

attaching it to the translation or rotation control stow straps (Restraint Harness Buckle Stowage

Straps

Diagram). This also

prevents the buckles and attachments from floating free during zero-g and

striking a crewman or equipment.

Restraint Harness

Buckle Stowage Straps Diagram

The harness will be on and locked during all maneuvers

when g-loads are expected such as launch, delta V, docking, entry, and

landing. The harness can be tightened and loosened readily by adjusting

the length of the strap. Pull on the hand grip to tighten. To loosen,

rotate the adjuster, allowing it to unlock and the strap can be

lengthened.

Handholds (Handholds, Hand Straps and Hand Bar Diagram)

Handholds,

Hand Straps and Hand Bar Diagram

Hand Bar (Handholds, Hand Straps and Hand Bar Diagram)

The hand bar is located on the MDC near the side hatch

and has two positions, stowed and extended. A lever at one end releases

the detent for moving from one position to the other. The hand bar

furnishes a place to hold when ingressing or egressing from the CM side

hatch. It will support the weight of a suited astronaut in 1 g. In zero g

during extravehicular activity or transfer, the hand bar can also be used

for ingressing or egressing through the side hatch.

During the CM landing, the legs and feet of the crewman

may jostle about unless restrained to the couch footpan. If in the

spacesuit, the boot heels and couch footpan interconnect and restrain the

feet and legs. However, if entry and landing is in shirtsleeves, or

inflight coveralls, the feet are held to the couch footpans by heel

restraints.

The heel restraints are hollow aluminum blocks that

attach to the heels of the crewman1 s booties by means of straps and

Velcro. The restraints connect to the footpan in the same manner as the

spacesuit booties.

Hand Straps (Handholds, Hand Straps and Hand Bar Diagram)

The hand straps serve as a maneuvering aid during a

g-load or zero-g condition.

The hand s traps are of fluorel covered cloth and are

attached by brackets at each end. There a r e five hand straps behind the

MDC and one on the left-hand equipment bay over the ECS filter access

panel and one each on the foot X -X struts. These straps lie flat against

the structure when not in use.

The hand s traps are of fluorel covered cloth and are

attached by brackets at each end. There a r e five hand straps behind the

M DC and one on the left-hand equipment bay over the ECS filter access

panel and one each on the foot X -X struts. These straps lie flat against

the structure when not in use.

Guidance and Navigation Station Restraint

Two positions may be utilized at the G&N station:

standing position or center couch G&N position. The astronaut will

restrain himself in the standing position by fastening his booties or

boots to the aft bulkhead and using the handholds on the G&N console.

The astronaut will restrain himself in the center couch

at the G& N station by positioning the couch to a 170-degree hip angle

and restraining his feet in the couch footpans .

Sleep Station Restraints (Sleep Station Restraints Diagram)

The crewman's sleeping positions will be in the right

couch and under the left and right couch with the l1ead toward the hatch.

He will be restrained in position by the crewman sleep station restraint.

Sleep Station

Restraints Diagram

The three restraints are beta fabric, lightweight

sleeping bags 64 inches long, with zipper openings for the torso and

7-inch-diameter neck openings. The two sleep restraints under the couches

are supported by two longitudinal straps. The two asleep restraints under

the couches are supported by two longitudinal straps that attach to the CO2 absorber stowage

boxes on one end (LEB), and to the CM inner structure at the other end. To

restrain the foot end, an additional strap on each side attaches to the CO2 absorber stowage

box brackets. The third restraint, for the right couch is just the

sleeping bag with no straps.

During the mission and shirtsleeve environment, a

crewman can unzip the restraint and slide in with his flight coveralls on.

However, if an emergency exists, and the crew are in their spacesuits,

they will be too large to enter the sleep restraint. In that case, the

crewman will lie on top of the restraint and hold himself in place by the

strap around the middle of the sleep restraint. In that case, the crewman

will lie on top of the restraint and hold himself in place by the strap

around the middle of the sleep restraint.

The sleep restraint will be rolled and strapped against

the side wall and aft bulkhead at launch. When needed, they will be

unrolled and attached to the CO2

absorber stowage boxes near the LEB or placed in the right couch.

During preparations for entry, two sleep restraints will e stowed in its

stowed position against the side wall. The other sleep restraint will be

detached from the side wall and placed in the center aisle, head end

toward the LEB. Three spacesuits will be stowed lengthwise in the

restraint, alternating the head-boot directions. The upper (or forward)

spacesuit will be stowed with the helmet on and protruding from the

restraint neckring. The spacesuit and the sleep restraint will be lashed

to the bulkhead using 5 ropes and brackets on the aft bulkheads and

lockers.

Flight Data Restraints (Flight Data Restraint Diagram)

The purpose of the flight data restraint, or bungee

system, is to position and retain the flight data charts, maps, and

manuals so the crew can view them during the mission. The system includes

long and short data-retention snap assemblies (bungees), long and short

data-retention hook assemblies (bungees), Calfax adapter plates, data card

clips, food door clips, data book spring clips, temporary stowage pouches,

and a debris closeout with pockets.

The bungees (retention snap and hook assemblies) are

0.25-inch-diameter steel springs, the “short” being 4 inches long and the

“long” being 8 inches long. The short bungees will stretch to 14 inches,

and the long will stretch to 34 inches for use. Attached at each end of

the bungee spring is a 3-inch length of Beta cloth with a female snap or

clip and a snap. The snap-type bungee attaches to bonded male snaps

(studs) on the panels or closeouts so they lie parallel and close to the

panel. The hook-type bungees hook on doors or switch wickets, whichever is

the most useful. The manuals or charts are slid between the bungee spring

and the panel and will stay in place.

There are four Calfax adapter plates that attach to

Calfax fittings adjacent to the G&N panel 122 with the use of the E

tool. Each adapter plate has two male snaps to which the snap-type bungees

will connect.

A data card clip is a small, steel clip with a female

snap on the rear. It attaches to a male stud on the panels or closeouts

and. will hold data cards.

The food door clips fasten to the B1 or L3 compartment

door. Bungees can be attached to and stretched between the c lips for

retention of flight data.

A female snap on the data book spring clips fastens to

any one of numerous male studs on the panels. The spring clip allows a

rapid exchange of manuals or data.

The number of restraints may vary from spacecraft to

spacecraft. The following list is approximate:

·

Snap bungees, short • • • • • • •

• • • 6

·

Snap bungees, long •

• • • • • • • • • 6

·

Hook bungees, short • • • • • • •

• • • 2

·

Hook bungees, long • • • • • • •

• • • 2

·

Calfax adapter plate, left • • •

• • • • • 2

·

Calfax adapter plate, right • • • • • • • 2

·

Data card clip

• • • • • • • • • • • • • • 8

·

Food door clip • • • • • • • • •

• • • • •6

·

Data book spring clip • • • • • •

• • • • 8

To verify the number, refer to the applicable

spacecraft “Apollo Stowage List (NASA document).”

Small, temporary stowage pouches (2), 15 inches in

length and have female snaps that attach to studs, in the crew

compartment, are made of Beta cloth with a bungee-type closure, and. have

small plastic viewing windows. The bungees, clips, and adapter plates are

stowed in the pouches prior to use and during entry.

The debris closeout with pockets has two purposes: to

restrict debris from entering the gaps after the lunar return containers

(rock boxes) replace the LiOH canisters in B5 and B6, and is the flight

data temporary stowage position after removing the data from the

compartment. The closeout is 42 inches long, has four pockets, is Beta

cloth, and attaches to the LEB with snaps. When removing LiOH boxes and

installing the rock boxes, remove only half of the closeout. When the

temporary stowage pouches are not being used, they can be stowed in the

closeout pockets with the flight data.

There are a number of straps used for restraint

purposes during zero g. The couch, probe, drogue, glare shield, control

cable, and cable routing straps have specific uses, whereas the utility

straps have numerous uses. Most of the straps are made of beta cloth and

use snaps as a rest raining method. The snaps have a male (stud) and

female (socket) component.

Control Cable Straps (Special Straps Diagram).

The rotation control cables exit the junction box on the aft bulkhead and

are routed along the 22 attenuator struts to the couch side stabilizer

beams. The control cables are held to the 22 struts by the control cable

straps, two on each strut. The straps are 1 inch wide and 11 inches long.

Each has four snaps, a pair to snap around the strut and a pair to hold

the cable.

(Center

Couch Restraint Straps Diagram). The center couch has to be

stowed for a LM DPS burn and EVA. For a LM DPS burn, the seat and legpan

is lowered to the aft bulkhead while the body support stays hinged at the

headbeam. The folded seat-legpan must be restrained to the aft bulkhead by

the DPS burn strap. The couch DPS burn strap is 29 inches long, with one

snap (stud) at one end and 6 snap sockets at the other end. It attaches to

a "D" ring on the A1 storage locker and around the knee control handle.

When not in use, the s trap is stowed in a locker.

(Center

Couch Restraint Straps Diagram). During the preparation for

EVA, the center couch is removed from its center position and stowed under

the left couch. The center couch is restrained to left couch by the two

center couch stow straps.

Center Couch

Restraint Straps Diagram

The "upper" center couch stow strap routes around the

headrest support bars and connects to itself. It is 24 inches long, has a

“D” ring at one end, a center flat rubber bungee section, and a snap-hook

at the other end.

The "lower" center couch stow strap routes through two

holes in the center couch body support at the seatpan. It is 43 inches

long, has a 12-inch bungee section, and a hook at each end which attaches

to "D" rings on the left couch body support near the seatpan. When not in

use, the straps are stowed.

(Special

Straps Diagram). The cable retainer strap is 5.5 inches long

with a back-to-back socket and stud at one end and a socket at the other

end. The socket/stud will attach to studs bonded on the structure and when

the socket is attached to the strap stud/ socket, it forms a loop. This

facilitates routing the TV camera cable and the translation control cable.

When not in use, the straps are left attached to a wall stud.

(Probe

and Drogue Stowage Straps Diagram). When required, the probe

is stowed under the seatpan and the drogue under the backpan of the right

couch. The two drogue stow straps are attached to the right body support

by one strap each. When not in use, the free end of the straps are

attached to the couch also.

Probe and Drogue

Stowage Straps Diagram

(Utility

Straps Diagram). The utility straps are named for their

versatility. They are used for holding looped straps and cables in stowage

lockers or compartments and for restraining other equipment to the

structure during the mission.

The utility straps are 12.5 inches long with two studs

and two sockets positioned so as to form two loops when snapped. One loop

will wrap around a piece of equipment and the other loop around structure

or will attach to structure by the snap.

MDC Glareshade Straps (Special Straps Diagram)

The MDC glareshade straps retain the MDC glareshades in

their R4 stowage compartment. The straps are 5 inches long with sockets at

both ends that snap onto studs bonded to the structure. One end of the

strap always stays attached.

Velcro and Snaps Retainer Locations

There are numerous 1-inch square patches of Velcro

located in the crew compartment. They are bonded to the structure and

control panels in accordance with crew and crew support requirements. Each

CM has a "Velcro and Snaps Map" designating the location of all retainers.

The drawing number is V36-6300XX, the XX being the CM numerical

designation plus 4. Example, the "Velcro and Snaps Map" for CM 112 is

V36-630016.

Tunnel Hatch Stow Bag (Center Couch Restraint Straps Diagram)

The tunnel hatch must also be stowed when required.

However, due to some remotely flammable materials, the hatch must be

stowed in a beta cloth bag with a circumferential zipper. The bag is

lashed under the left couch by straps and remains there. When the center

couch is stowed under the left couch, the stow bag is collapsed between

the couches.

Sleep Restraint Tie down Ropes

During entry preparation for an unsuited entry, the

spacesuits are stowed in a sleep restraint and lashed down in the center

aisle by ropes.

A rope is a PBI (polybenzimidazole) fiber, 10-feet

long, and has plastic ferrules on the ends to prevent fraying, there are

five ropes stowed. Miscellaneous restraints are shown in figure

2.12-16.

Figure 2.12-16.

Miscellaneous Restraint

SIGHTING AND ILLUMINATION AIDS

Sighting and illumination aids are those devices,

lights, or visual systems that aid the crew in the accomplishment of their

operational mission. This handbook describes the internal sighting aids

first and the external second. The crew compartment floodlights and panel

lighting is described in the electrical power system

Electrical section of this handbook.

Internal Sighting and Illumination Aids (Internal Sighting and Illumination Aids Diagram)

Internal

Sighting and Illumination Aids Diagram

Internal sighting and illumination aids include window

shades for controlling incoming light, internal viewing mirrors, the

crewman I optical alignment sight for docking and aiming the data

acquisition camera, a LM active docking target for LM to CM docking,

window markings for monitoring entry, a monocular for lunar survey, and

some miscellaneous items such as floodlight glareshields, MDC glareshades,

and an eyepatch.

Window Shades (Window Shades and Mirrors Diagram)

The CSM has five windows: two triangular-shaped

rendezvous windows, two square-shaped side windows, and a hatch window.

Periodically, the light coming through these windows has to be restricted.

This is accomplished by window shades (Window Shades and Mirrors Diagram).

Window Shades and

Mirrors Diagram

The window shades are aluminum sheets held on by "wing"

latches. The shades are 0.020-inch thick with a frame of 0.250 inch. The

shade has a gasket on the "light" side which seats against the window.

Each window frame has three wing latches, or two latches and a clip, that

res train the shade on the window. The shades are stowed in a stowage bag

in the upper equipment bay.

When the astronaut is in a pressurized spacesuit on the

couch, his field of vision is very limited. He can see only to the lower

edge of the main display console (MDC), thus "blanking out" his stomach

area where his restraint harness buckling and adjustment takes place. The

function of the internal viewing mirrors is to aid the astronaut in

buckling and adjustment of the restraint harness, locating couch controls

and spacesuit connectors. By positioning all the mirrors to view the MDC

from the LEB, the CMP can periodically monitor the instruments while in

lunar orbit.

There are three mirrors, one for each couch position.

The mirrors for the left and right astronaut are mounted on the side of

the lighting and audio control console above the side viewing window and

fold. The center astronaut's mirror is mounted on the right X-X head

attenuator strut.

The mirror assembly consists of a mounting base, a

two-segmented arm, and a mirror. The mirror is rectangular (4.25 by 3.5

inches), flat, and steel with an aluminized surface. The two-segmented arm

allows a reach of approximately 22 inches from the mount. The arms have

swivel joints with a friction adjustment to position the mirrors in the

desired angles. The friction is adjusted with tool R, a torque set driver.

The mirrors are locked in position by a clamp during boost and entry.

Crewman Optical Alignment Sight (COAS) (Crewman Optical Alignment Sight System Diagram)

Crewman

Optical Alignment Sight System Diagram

The primary function of the crewman optical alignment

sight (COAS) is to provide range and range rate to the CM or LM pilot

during the docking maneuver. The closing maneuver, from 150 feet to

contact, is an ocular kinesthetic coordination of the astronaut

controlling the CM with economy of fuel and time.

A secondary function of the sight is to provide the

crewman a fixed line -of-sight attitude reference image which, when viewed

through the rendezvous window, appears to be the same distance away as the

target. This image is boresighted (by means of a sight mount) parallel to

the centerline (X-axis of the CM) and perpendicular to the Y- Z plane.

The crewman optical alignment sight (COAS) is a

collimator device, similar to the aircraft gunsight, weighing

approximately 1-1/2 pounds, is 8 inches long and requires a 28-vdc power

source. The COAS consists of a lamp with an intensity control, reticle,

barrelshaped housing, mount, combiner assembly, filter, and a power

receptacle. The reticle consists of a 10-degree circle (figure 2. 12-20),

vertical and horizontal cross hairs with 1-degree marks, and an elevation

scale (on the side) of -10 to +31. 5 degrees. The elevation scale is seen

through an opening or window.

The COAS is stowed in amount by the left side window at

launch and entry, and other periods as the mission requires. Two spare

lamps are stowed in U 3. The COAS can be mounted on the right or left

rendezvous window.

The receptacle is de-energized by placing switch on

panel 16 (right) or 15 (left) to the OFF position. If sighting at

extremely bright sunlight, the filter is unstowed, and installed between

the barrel and combiner by looping tether around the barrel, positioning

the filter approximately parallel with the combiner, and pressing onto

barrel by engaging clips. Do not slide filter on combiner frame or damage

may result to clips. Install COAS on the window mount and energize circuit

by placing switch to ON.

For the left window operations, the barrel index is

matched with LW by unlocking the barrel lock and rotating the barrel until

the detent seats. For right window operations, use the RW index mark.

There may be a little play when the de tent seats. To duplicate the bore

sighted condition, the barrel must be snugged or rotated against the

detent. The direction of rotation is on the sidewall near each COAS mount.

To turn lamp on, turn intensity control clockwise until

the reticle appears on the combiner glass at the required brightness. The

actual usage and visual presentations will be discussed in

Docking and Transfer.

While photographing activities or scenes outside the

spacecraft with the 16 mm data acquisition camera, the COAS is used to

orient the spacecraft and aim the camera. The camera will be mounted in

the right window.at a 90-degree angle to the X - axis, and will be

shooting out the right rendezvous window, via a right angle mirror

assembly.

A constant angle on a star during a differential

velocity maneuver (MTVC) can be maintained by use of the elevation scale.

The barrel lock is lifted and turned so the barrel can be rotated, and

will hold in an intermediate position by friction. The elevation will be

read on the elevation scale using the horizontal "line" of the reticle as

the index.

LM Active Docking Target (LM Active Docking Target Diagram)

LM Active Docking

Target Diagram

After lunar rendezvous and acquisition, the LM

approaches the CM from the forward end. At 50 feet, the LM pitches 90

degrees for the final approach, during which the LM Commander will sight

through the overhead window, using the LM COAS for alignment. The LM

overhead window will align on the CM right rendezvous window. The LM

docking target will be placed in the CM right rendezvous window to

function as a guide to the LM Commander.

The LM active docking target is a collapsible target of

similar configuration as the LM docking target but approximately half the

size. The base is 8 inches in diameter with green electroluminescent (EL)

lamps and a black stripe pattern on the front. The airplane, or stand-off

cross, is li t by a red incandescent lamp and its support strut folds for

stowing. When folding the strut, failure to slide the nut more than 1 /2

inch from the pivot point may result in damage to the face of the target.

The adapter support strut is removable, fits into the base slotted stud,

and is secured by a 1-inch nut that should be hand tightened only. When

assembling the adapter support strut to the base, align the white indices

on the base and adapter.

Tl1e base has a power cord for connection to panel 16

near the right-side viewing window. It operates on ac, and is powered from

the LIGHTING RUN/EVA/TGT-AC2 right CB on auxiliary CB panel 226. The light

is controlled by the DOCKING TARGET switch on MDC-16 and has three

positions: OFF, DIM, and BRIGHT.

F or support during usage, the mounting support strut

slides into the right COAS mount on the right rendezvous window frame. The

target is stowed in U3 Locker on the side wall near the aft bulkhead and

side hatch.

Remove the target from the U3 locker, extend the strut,

and lock in place with locknut. Remove the adapter support strut from U3

and attach to the base. Verify right LIGHTING RUN/EVA/ TGT-AC2 CB on panel

226 is closed and the DOCKING TARGET switch on MDC - 2 is OFF. Insert

target mount strut slide into COAS mount until it seats fully. When fully

seated, the power connector will be mated.